Advanced Precision Machining Across USA

Fedele Autocore stands at the forefront of precision CNC milling services throughout USA, delivering exceptional machined components that meet the most stringent quality requirements. Our advanced milling capabilities combine cutting-edge technology with skilled craftsmanship to produce complex geometries, intricate features, and high-precision parts across diverse industries.

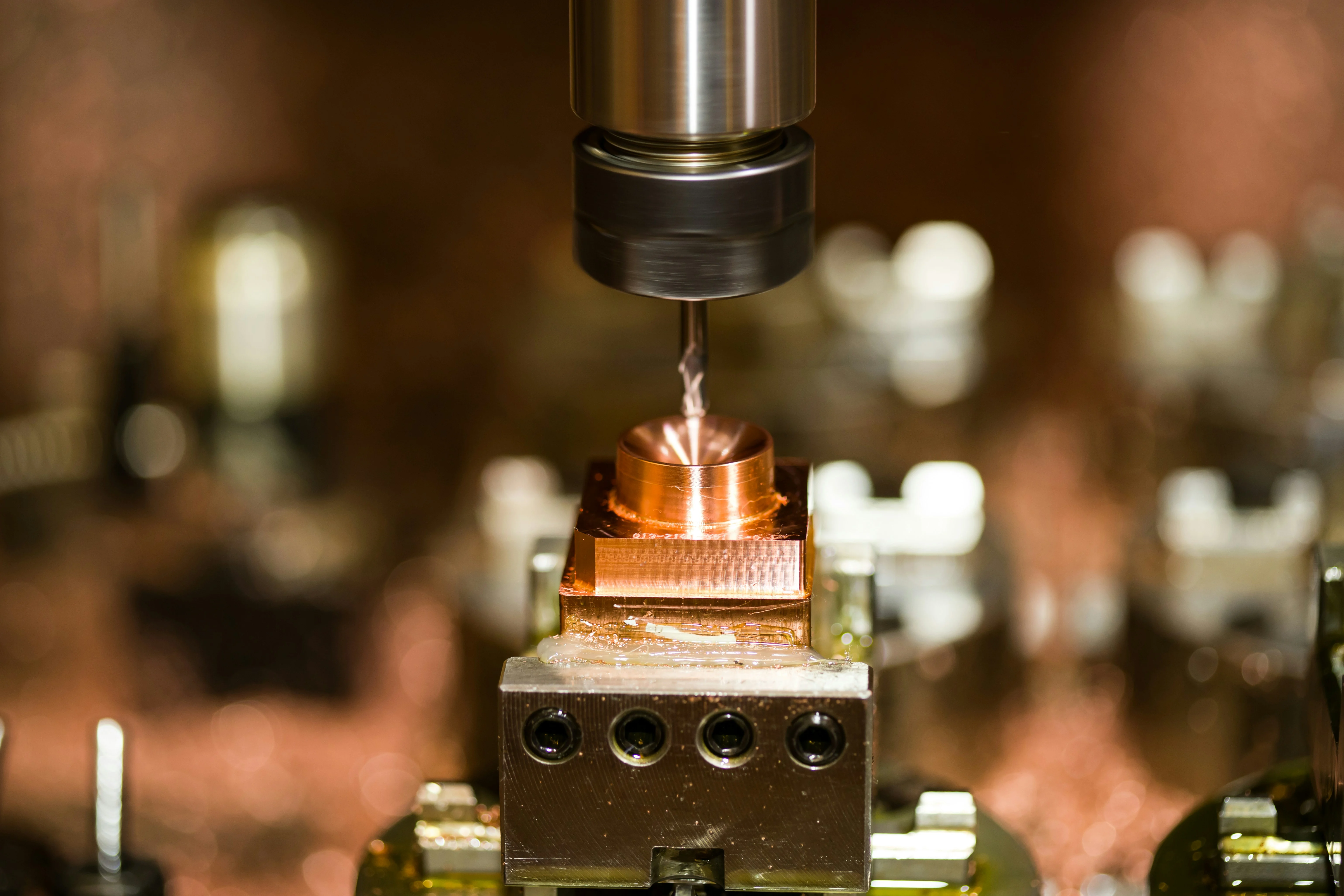

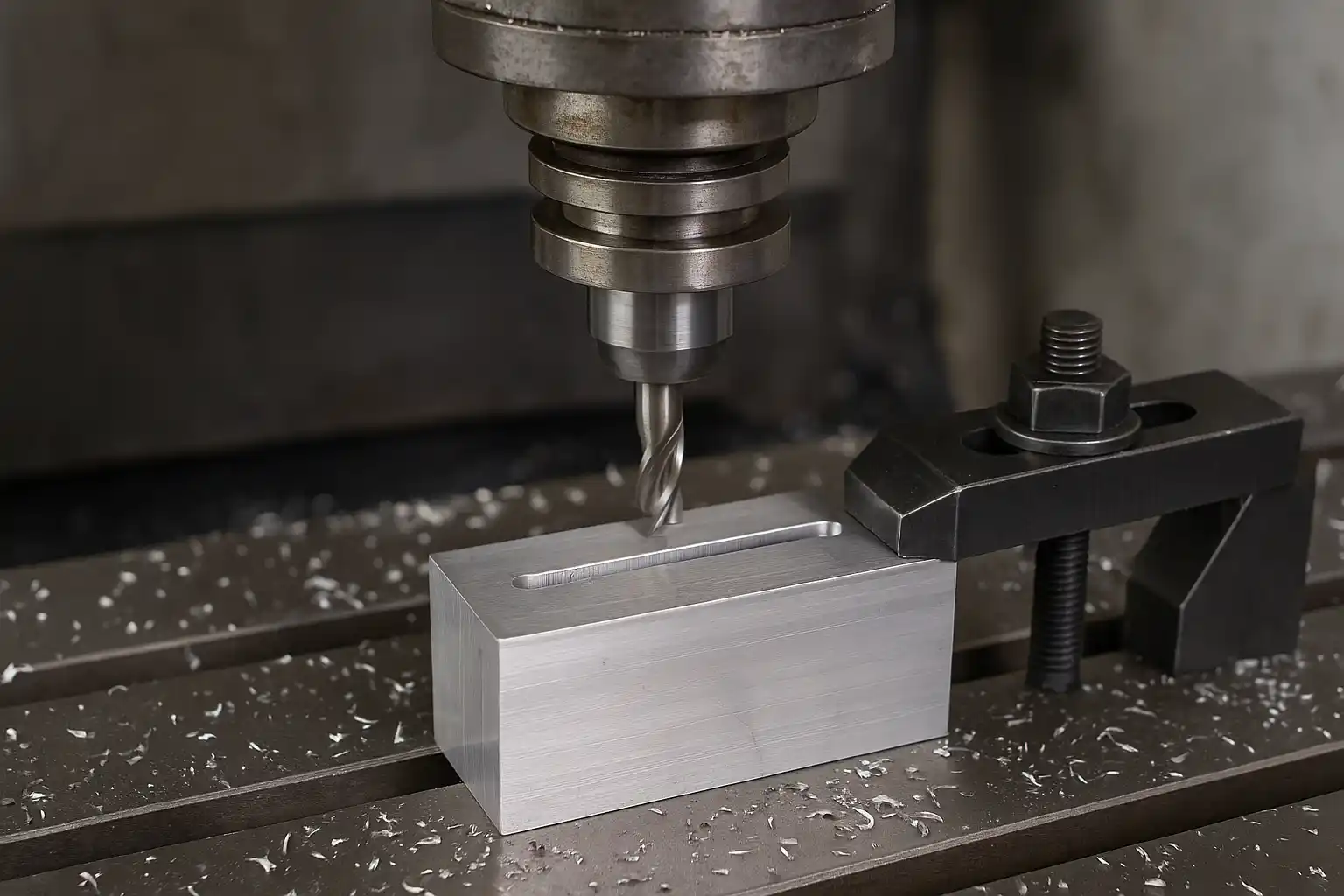

CNC milling is a versatile subtractive manufacturing process where computer-controlled rotating cutting tools remove material from stationary workpieces to create precise shapes, slots, holes, and complex three-dimensional features. This technology enables the production of both simple and highly complex components with outstanding accuracy and repeatability.

CNC milling operations utilize multi-axis machine tools where rotating cutters move along programmed tool paths to precisely remove material from workpieces. Unlike turning operations where the workpiece rotates, milling involves stationary parts while the cutting tools rotate and traverse multiple axes simultaneously. This approach enables the creation of flat surfaces, angular features, complex contours, pockets, and intricate three-dimensional geometries.

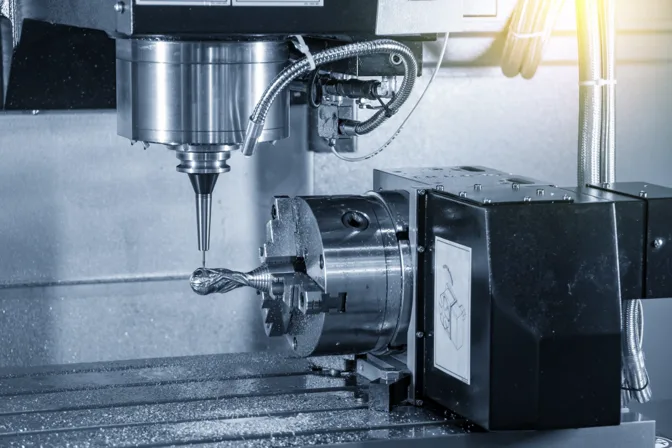

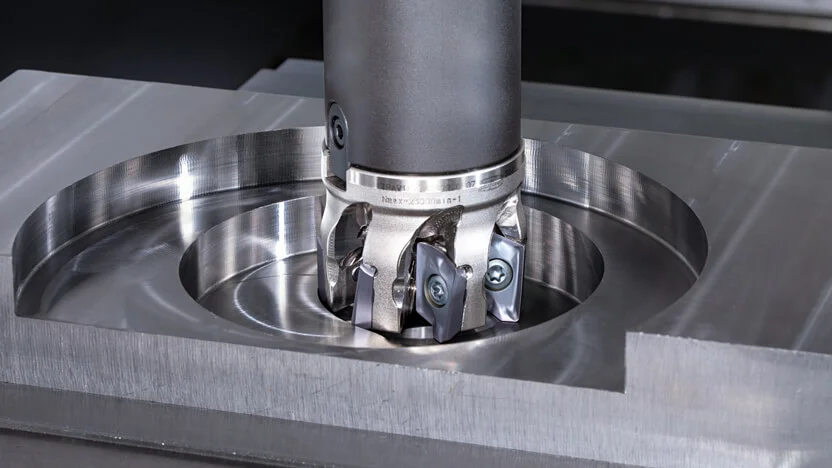

Modern CNC milling centers offer multi-axis capabilities including 3-axis, 4-axis, and 5-axis simultaneous machining, allowing for the production of complex parts in single setups while maintaining exceptional dimensional accuracy and surface finish quality.

Standard vertical and horizontal milling operations for plates, blocks, and basic geometries. Perfect for slots, pockets, holes, and flat surface machining with excellent precision and efficiency.

Rotary axis capability enables machining of cylindrical features, helical surfaces, and complex angular geometries. Ideal for parts requiring continuous contouring and multi-sided machining.

Advanced simultaneous 5-axis machining for complex aerospace components, medical devices, and intricate geometries requiring superior surface finish and dimensional accuracy.

Our extensive milling capabilities encompass a wide range of operations designed to meet diverse manufacturing requirements across multiple industries.

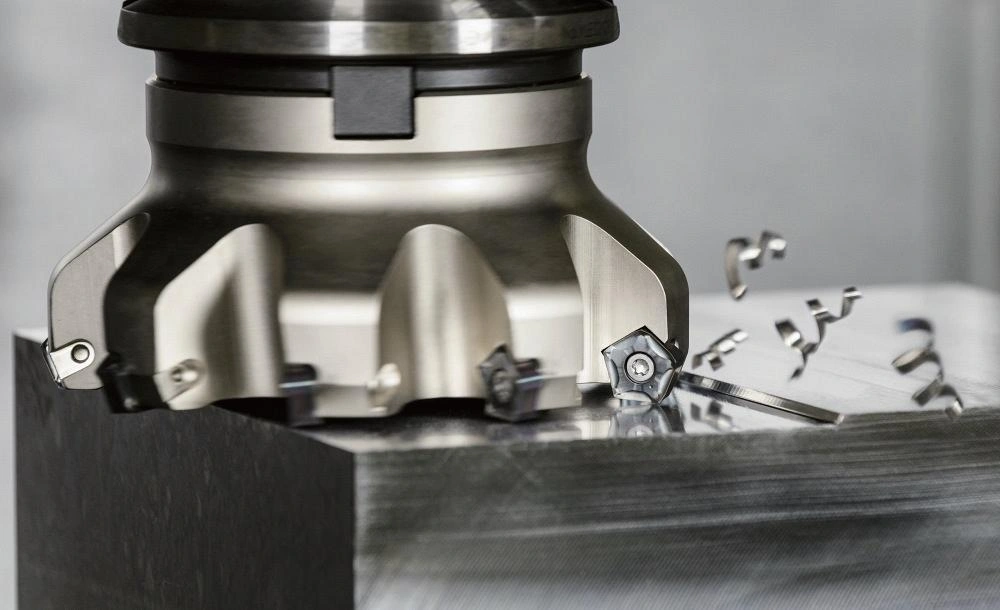

Creating flat surfaces perpendicular to the spindle axis with excellent surface finish and dimensional accuracy for critical mating surfaces.

Versatile cutting operations for slots, pockets, contours, and complex profiles using end mills of various geometries and sizes.

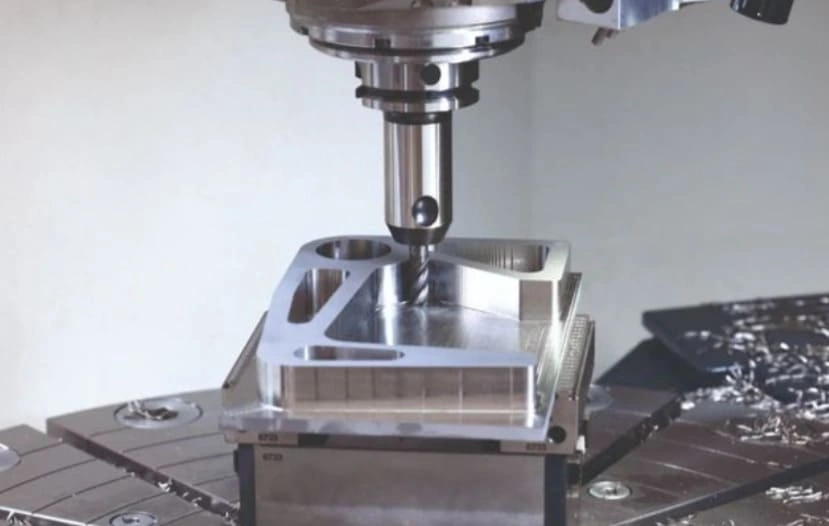

Removing material to create recessed areas, cavities, and complex internal geometries with precise depth control and smooth wall finishes.

Following complex curved paths to create intricate profiles, artistic features, and organic shapes with exceptional accuracy.

Precision hole creation, reaming, and thread cutting operations for fastener holes, fluid passages, and threaded connections.

Creating keyways, T-slots, dovetails, and custom profiles for mechanical connections and specialized applications.

Creating perpendicular steps and right-angle ledges with flat surfaces for precise assembly interfaces, mechanical stops, & component seating.

Machining angled surfaces, bevels, and chamfers using tilted cutters or spindle positioning for precise angular features.

Our precision CNC turning services support diverse industries across USA, delivering components that meet stringent quality and performance requirements.

Mission-critical components meeting strict defence standards for military, naval and aerospace applications.

Offshore drilling, subsea equipment, pipeline components and LNG facility parts.

Engine components, transmission parts, performance automotive and motorsport components.

Heavy machinery parts, infrastructure components and construction equipment solutions.

Power generation, renewable energy, grid infrastructure and energy storage components.

Hydraulic cylinders, valve components, pump parts and mining hydraulic systems.

Farm machinery parts, tractor components, agricultural equipment and rural machinery solutions.

Aircraft components, satellite parts, drone components and aerospace prototyping.

Our experienced engineers analyze your specifications, review CAD models, and provide design optimization recommendations to enhance manufacturability and reduce costs while maintaining performance requirements.

We procure certified materials from trusted suppliers, conduct incoming inspection, and prepare raw stock to precise dimensions ensuring optimal machining results.

Skilled programmers create optimized CNC programs using advanced CAM software, select appropriate cutting tools, and configure machine setups for maximum efficiency and precision.

Components are machined using state-of-the-art CNC milling centers with real-time monitoring to ensure dimensional accuracy, surface finish quality, and adherence to specifications.

Every part undergoes comprehensive dimensional inspection using coordinate measuring machines (CMM), surface roughness testing, and visual inspection to verify conformance to specifications.

Parts receive specified surface treatments, coatings, or secondary operations followed by careful packaging and prompt delivery to meet your project timelines.

Our advanced CNC milling capabilities deliver exceptional precision and quality across a wide range of part sizes and complexities.

±0.002mm (±0.0001")

2000mm × 1000mm × 800mm

Ra 0.1µm achievable

Up to 65 HRC

3, 4, and 5-axis simultaneous

Up to 20,000 RPM

Fedele Autocore maintains comprehensive quality management systems ensuring every milled component meets or exceeds customer expectations. Our quality assurance encompasses incoming material verification, in-process monitoring, statistical process control, and final inspection using calibrated precision measuring equipment.

State-of-the-art multi-axis CNC milling centers with the latest control systems.

Highly skilled machinists, programmers, and quality technicians with decades of experience.

Comprehensive coverage across USA

Efficient operations and strategic partnerships deliver exceptional value.

Full technical assistance from concept through production.

Streamlined processes and efficient scheduling for fast delivery.

Tailored approaches for unique requirements and specialized applications.

Stock holding and scheduled delivery programs available.

Ongoing investment in technology and process optimization.

Beyond standard milling operations, Fedele Autocore offers specialized services to meet unique manufacturing challenges and demanding application requirements.

Our high-speed machining capabilities enable rapid material removal with exceptional surface finishes, particularly beneficial for aluminum aerospace components, thin-wall parts, and intricate details requiring minimal post-processing.

Machining hardened materials up to 65 HRC eliminates the need for EDM operations in many applications, providing superior surface finishes and dimensional accuracy for tool and die components, molds, and wear-resistant parts.

Precision micro-machining capabilities for small, intricate components requiring exceptional accuracy. Ideal for medical devices, electronics, and precision instruments where traditional machining methods are inadequate.

Our facility accommodates large components up to 2 meters in length, suitable for aerospace structures, industrial equipment bases, and oversized custom components requiring precision machining.

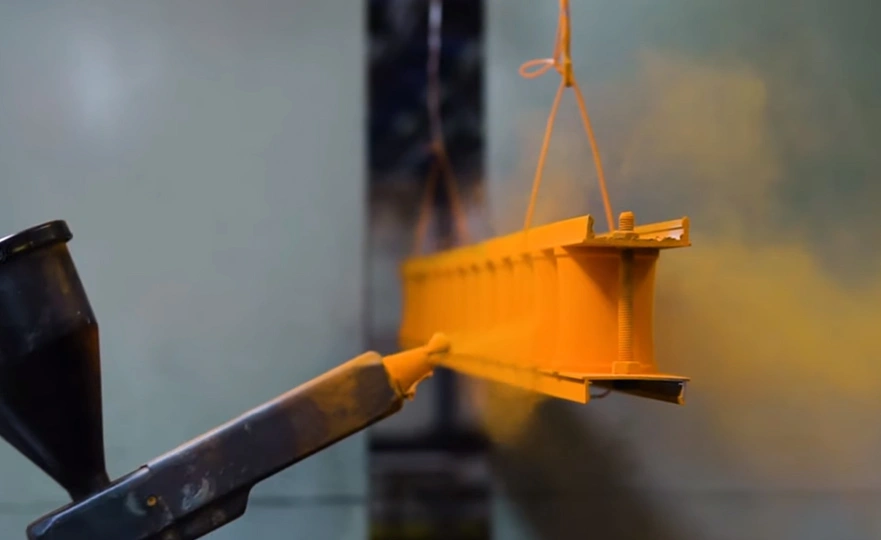

Fedele Autocore provides comprehensive surface finishing services to meet specific functional and aesthetic requirements:

Type II and Type III hard anodizing for aluminum components.

Nickel, chrome, zinc, and specialized coatings for corrosion protection.

Durable, environmentally friendly finish in various colors and textures.

Uniform matte finishes and surface preparation.

Mirror finishes for optical and aesthetic applications.

Stress relieving, hardening, and tempering services.

Our engineering team provides comprehensive Design for Manufacturing support to optimize your components for CNC milling processes:

Fedele Autocore maintains compliance with industry-specific standards and certifications:

Aerospace quality management system certification.

International quality management standard.

International Traffic in Arms Regulations compliance.

National Association of Testing Authorities recognition.

Experience the excellence of Fedele Autocore's CNC milling services. From concept to completion, our team delivers precision-machined components that exceed expectations and drive your success.

Get Your Quote Today