Built for Mission-Critical Components in Military Environments

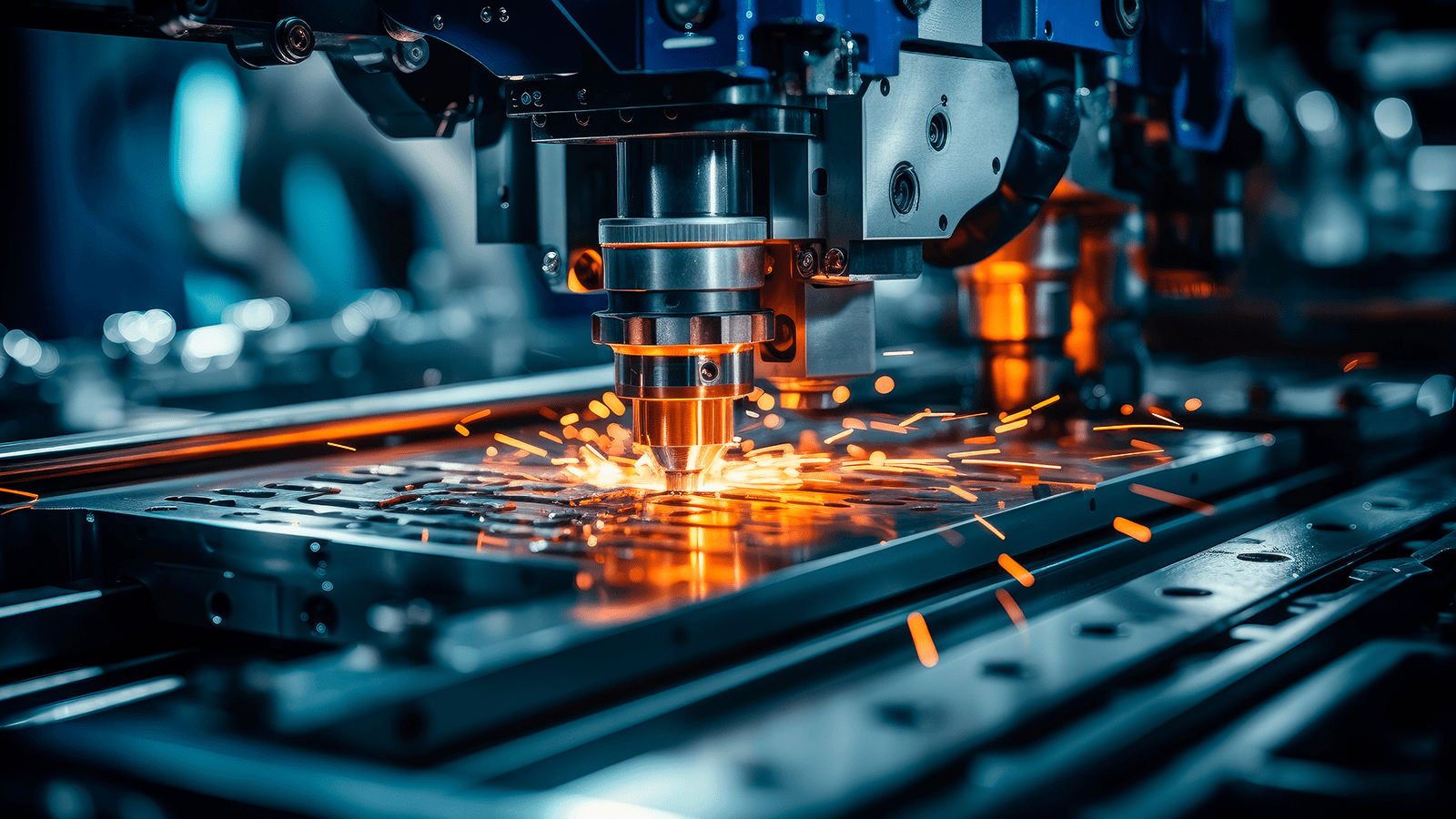

Fedele Autocore is committed to delivering high-precision CNC components for military and defense applications. Our manufacturing capabilities support mission-critical requirements where reliability, accuracy, and performance are non-negotiable. We produce components for armored vehicles, weapon systems, aerospace defense, and communication equipment.

Every component undergoes strict inspection and traceability protocols to meet MIL-SPEC and international defense standards. Our advanced CNC machining centers ensure consistent precision and strength for parts operating in extreme conditions.

Machining Precision

Compliance Standards

Production Readiness

Quality Assurance

Precise tolerances and surface finishes for reliability.

Rugged components for military vehicles under extreme conditions.

Critical aerospace components for defense aviation.

Shipboard systems and equipment for naval defense.

High-performance components for defense electronics.

Enhanced survivability with advanced armor elements.

Custom solutions for confidential defense applications.

Our facility maintains appropriate security clearances and compliance with military specifications (MIL-SPEC), International Traffic in Arms Regulations (ITAR), and other defense-related requirements. We understand the critical nature of military applications and maintain the highest standards of quality and security.

Military components often require specialized materials including armor steels, titanium alloys, and advanced composites. Our manufacturing processes include specialized heat treatments, surface hardening, and protective coatings designed to meet military environmental and performance requirements.

Military components undergo extensive testing and inspection including dimensional verification, material certification, non-destructive testing, and performance validation. We maintain complete traceability and documentation as required by military procurement standards.

State-of-the-art CNC machining centers with multi-axis capabilities, high-speed machining, and precision tooling systems.

Comprehensive quality management systems including ISO certifications, SPC, and advanced inspection equipment.

Experience with a wide range of materials from steels and aluminum to exotic superalloys and composites.

In-house engineering for design optimization, manufacturability analysis, and process development.

Proven track record of on-time delivery with flexible scheduling to meet urgent requirements and production demands.