Precision CNC Machining Services in Texas

Texas' energy-driven economy and diverse manufacturing landscape create unique demands for precision engineering. Our CNC machining services are specifically designed to serve the state's oil & gas, aerospace, energy, and industrial sectors with components engineered for demanding operational environments.

Engineered for Texas' industrial powerhouse, our facilities specialize in components that withstand extreme heat, pressure, and demanding operational conditions. We serve Texas' dominant oil & gas sector with precision downhole components and refinery equipment parts, support the state's thriving aerospace industry with flight-critical components, provide energy sector solutions for power generation and renewable installations, and deliver heavy industrial machinery parts built for continuous operations. Our strategic locations across Texas ensure rapid response and delivery throughout the state's major industrial centers.

Temperature Rated

Certified

Grade

Operations

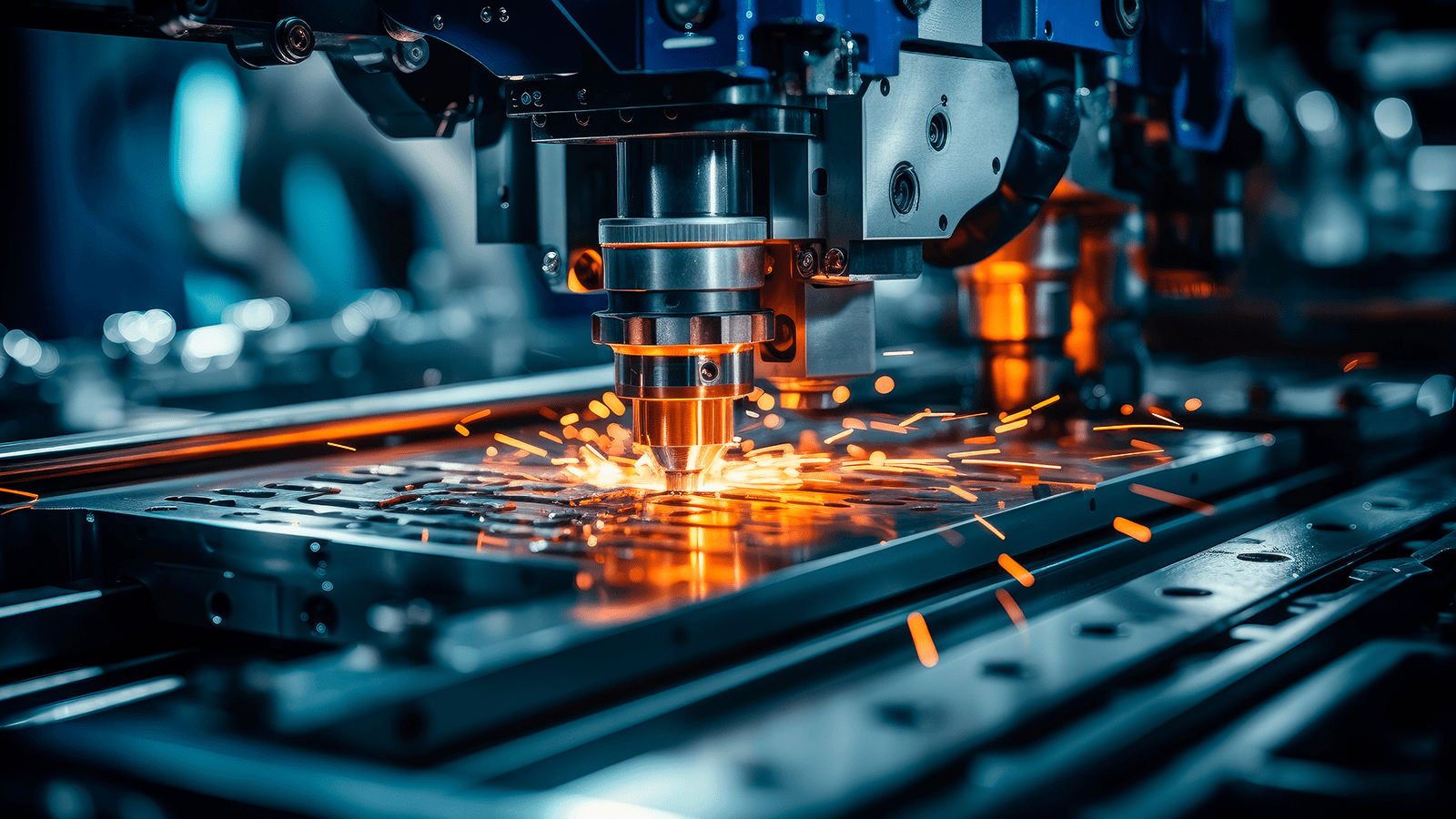

Texas' role as America's energy capital and manufacturing powerhouse requires precision machining services that understand the demands of heavy industry, high-temperature applications, and continuous operations. Our CNC machining processes are optimized for the challenging conditions and stringent requirements of Texas' key industrial sectors.

From Houston's petrochemical complexes to Dallas-Fort Worth's aerospace manufacturers, from West Texas oil fields to Gulf Coast refineries, we understand Texas' diverse manufacturing ecosystem. Our facilities maintain the capacity, expertise, and rapid response capabilities essential for supporting the state's 24/7 industrial operations.

Our CNC machining services support Texas' most critical industries with advanced manufacturing capabilities and specialized expertise.

Downhole tools, refinery equipment, pipeline components and offshore platform parts.

Aircraft components, satellite systems, defense applications and space exploration parts.

Power generation, wind turbines, solar installations and grid infrastructure components.

Heavy machinery, petrochemical equipment, processing systems and industrial components.

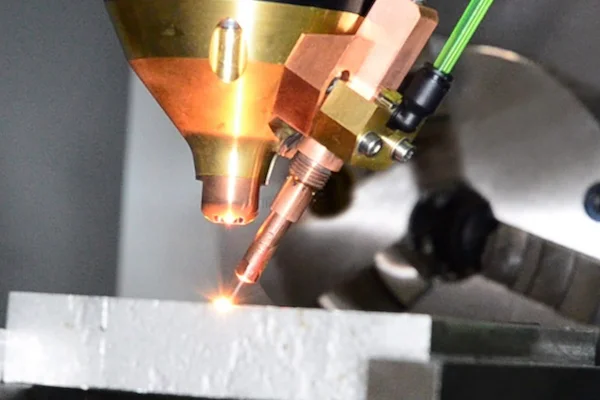

Specialized machining of exotic alloys including Inconel, Hastelloy, and titanium for high-temperature oil & gas applications, aerospace components, and industrial processing equipment operating in extreme conditions.

Precision manufacturing of ASME-compliant pressure vessel components, flanges, and fittings with complete material traceability and certification for oil & gas, petrochemical, and industrial applications.

Heavy-duty CNC equipment with large work envelopes capable of handling substantial industrial components for oil field equipment, refinery machinery, and large-scale manufacturing operations throughout Texas.

Round-the-clock emergency machining services supporting Texas' continuous industrial operations with rapid turnaround capabilities for critical equipment repairs and unplanned maintenance requirements.

Absolutely. We specialize in downhole tools, wellhead components, refinery equipment parts, and pipeline fittings with materials and certifications meeting industry standards for pressure and temperature.

Yes, we're AS9100 certified and work extensively with Texas aerospace companies including aircraft manufacturers, space exploration projects, and defense contractors requiring precision components.

Yes, our heavy-duty CNC equipment can accommodate large components for refineries, petrochemical plants, and industrial facilities with capacity for substantial workpieces and heavy materials.

We offer 24/7 emergency machining services with rapid response capabilities for critical equipment repairs, minimizing downtime for refineries, production facilities, and industrial operations.

Yes, we provide complete material traceability and certifications including mill test reports, chemical analysis, and mechanical properties documentation required for oil & gas applications.