Fedele Autocore - Your Premier Manufacturer in Iowa

At Fedele Autocore, we understand that Iowa's agricultural sector demands nothing less than perfection. Our CNC parts in Iowa are manufactured using cutting-edge technology and rigorous quality control processes to ensure every component meets the exacting standards of agricultural equipment manufacturers.

Our manufacturing capabilities support both OEM production and aftermarket replacement parts for major tractor brands and specialized farming equipment. We work with wear-resistant steels, corrosion-resistant materials, and heat-treated alloys to produce bushings, pins, gears, sprockets, and custom machined components that deliver exceptional durability. With fast turnaround times and competitive pricing, we help farmers minimize downtime during critical planting and harvest seasons.

Years Experience

Farm Parts Produced

Quick Turnaround

Precision Tolerance

At Fedele Autocore, we understand that Iowa's agricultural sector demands

nothing less than perfection. Our CNC parts in Iowa are manufactured using

cutting-edge technology and rigorous quality control processes to ensure

every component meets the exacting standards of agricultural equipment manufacturers.

Our comprehensive range of CNC machined components includes:

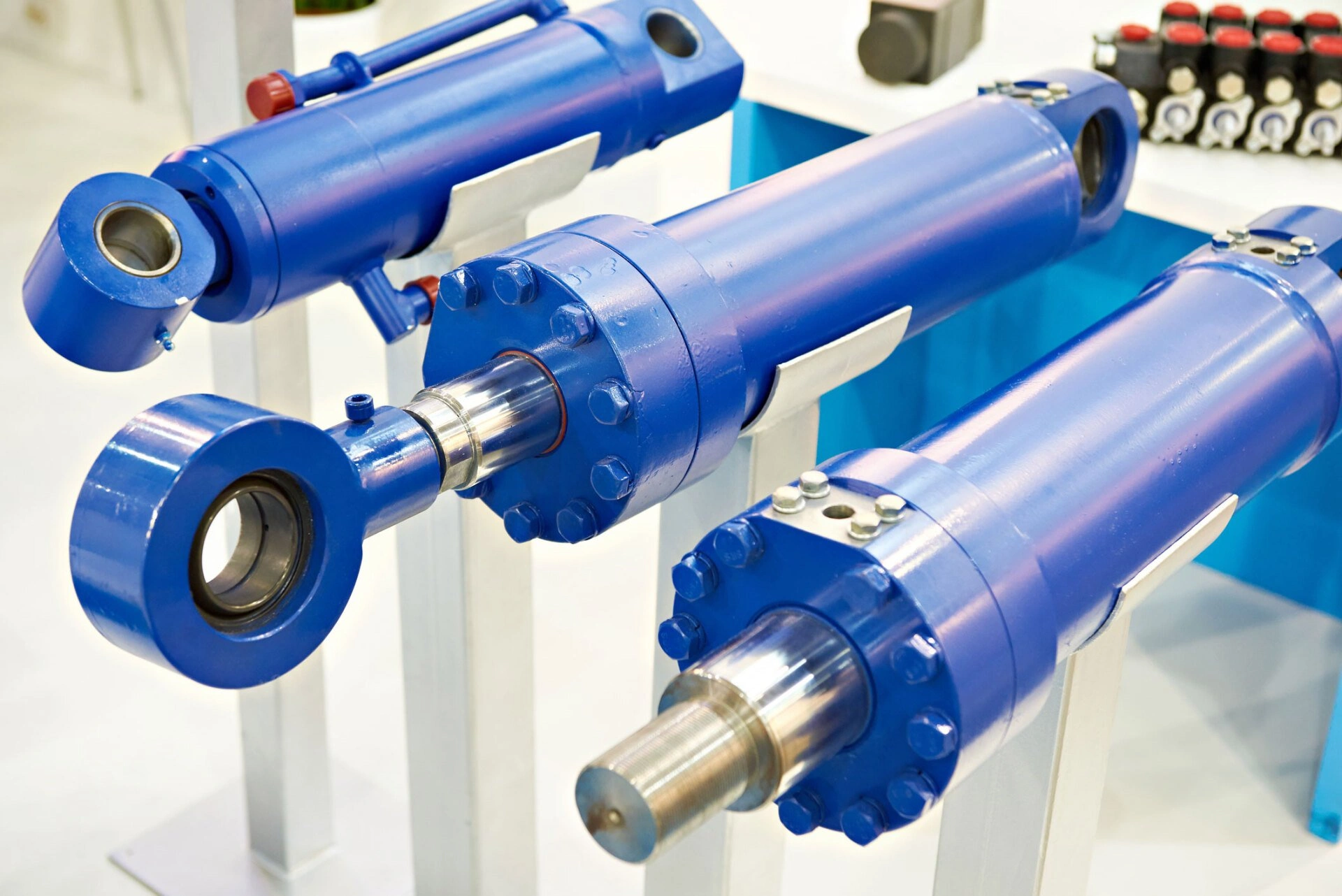

a) Hydraulic cylinders and pistons for lifting mechanisms

b) Valve bodies for hydraulic control systems

c) Manifolds for fluid distribution systems

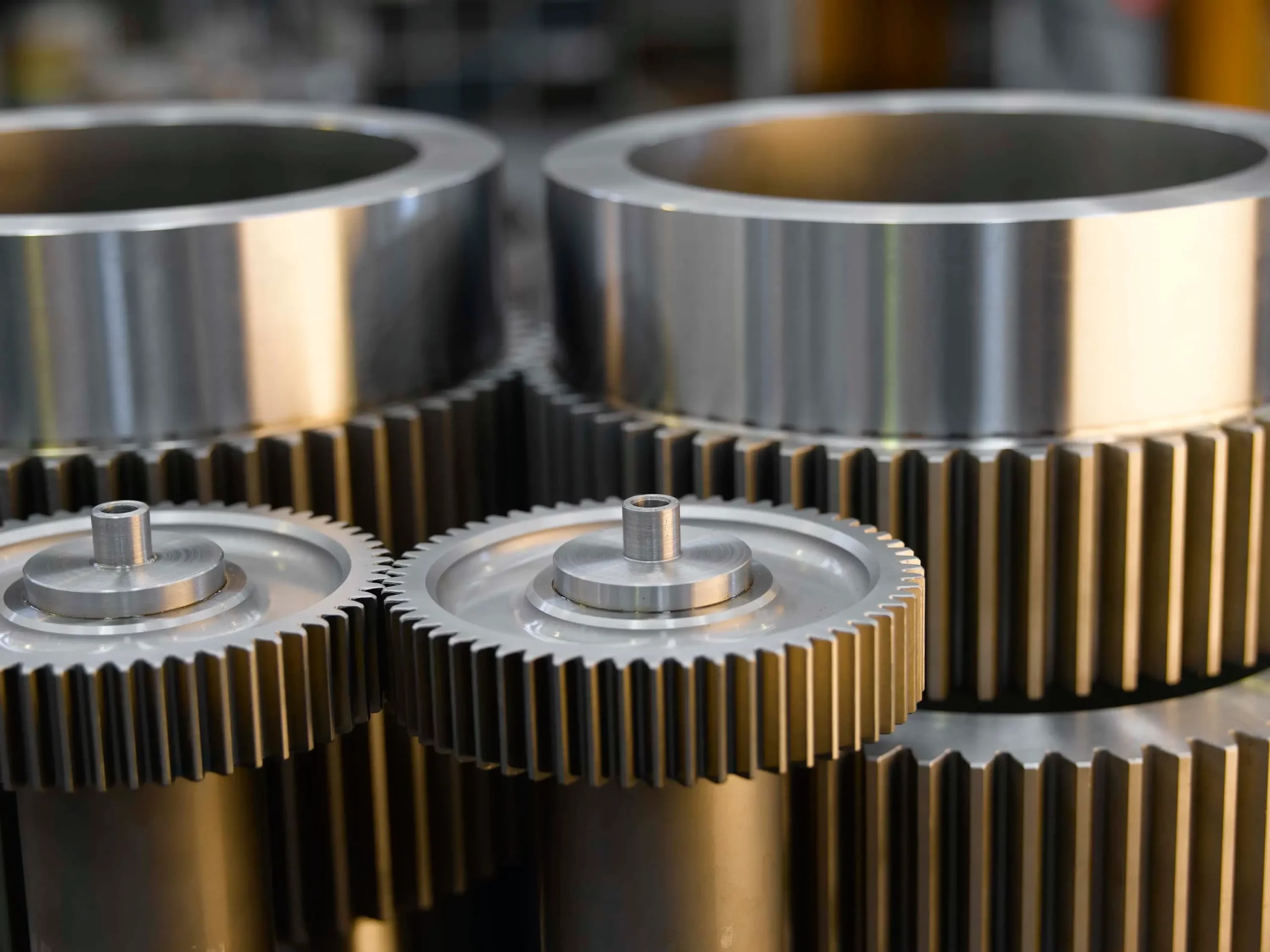

a) Precision transmission gears for power transfer systems

b) Splined hubs for efficient power transmission

c) Custom shafts and drive components

a) Tillage tool components including cultivator parts and plow shares

b) Harvester components such as cutting blades and feed mechanisms

c) Engine mounts and structural brackets

Our agriculture equipment precision parts in Iowa are manufactured to tolerances that exceed industry standards. We understand that in agricultural equipment, precision isn't just about performance – it's about reliability during critical farming seasons when downtime isn't an option.

a) Bore diameter precision: ±0.0005" to ±0.001"

b) Piston diameter accuracy: ±0.0002" to ±0.0005"

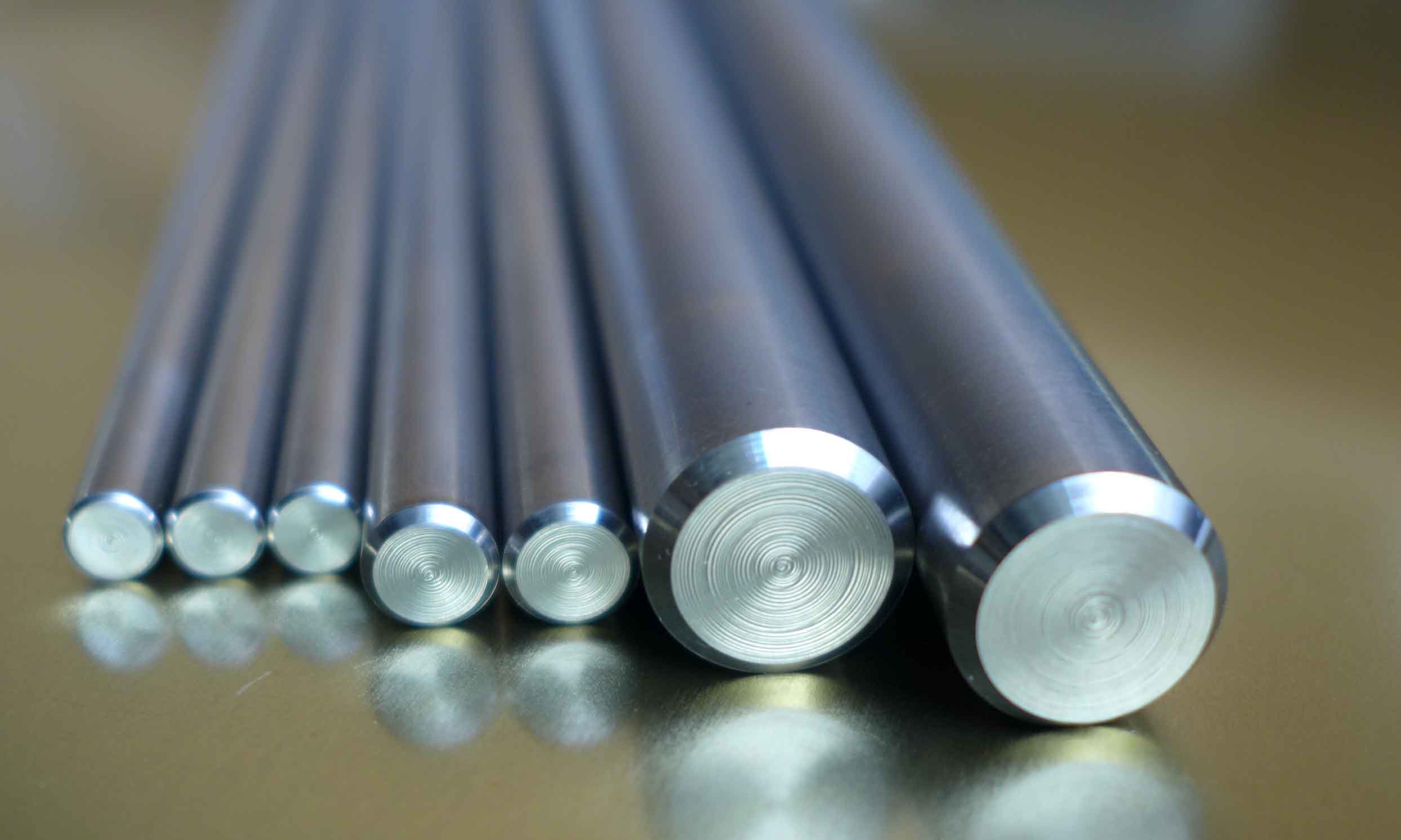

c) Rod diameter tolerance: ±0.0002"

a) Gear teeth precision: ±0.0002" to ±0.0005"

b) Pitch diameter accuracy: ±0.0002"

c) Shaft bore tolerances: ±0.0002"

a) Bore tolerances: ±0.0005"

b) Port dimension accuracy: ±0.001"

c) Mounting surface precision: ±0.005"

a) Custom mounting brackets and support structures

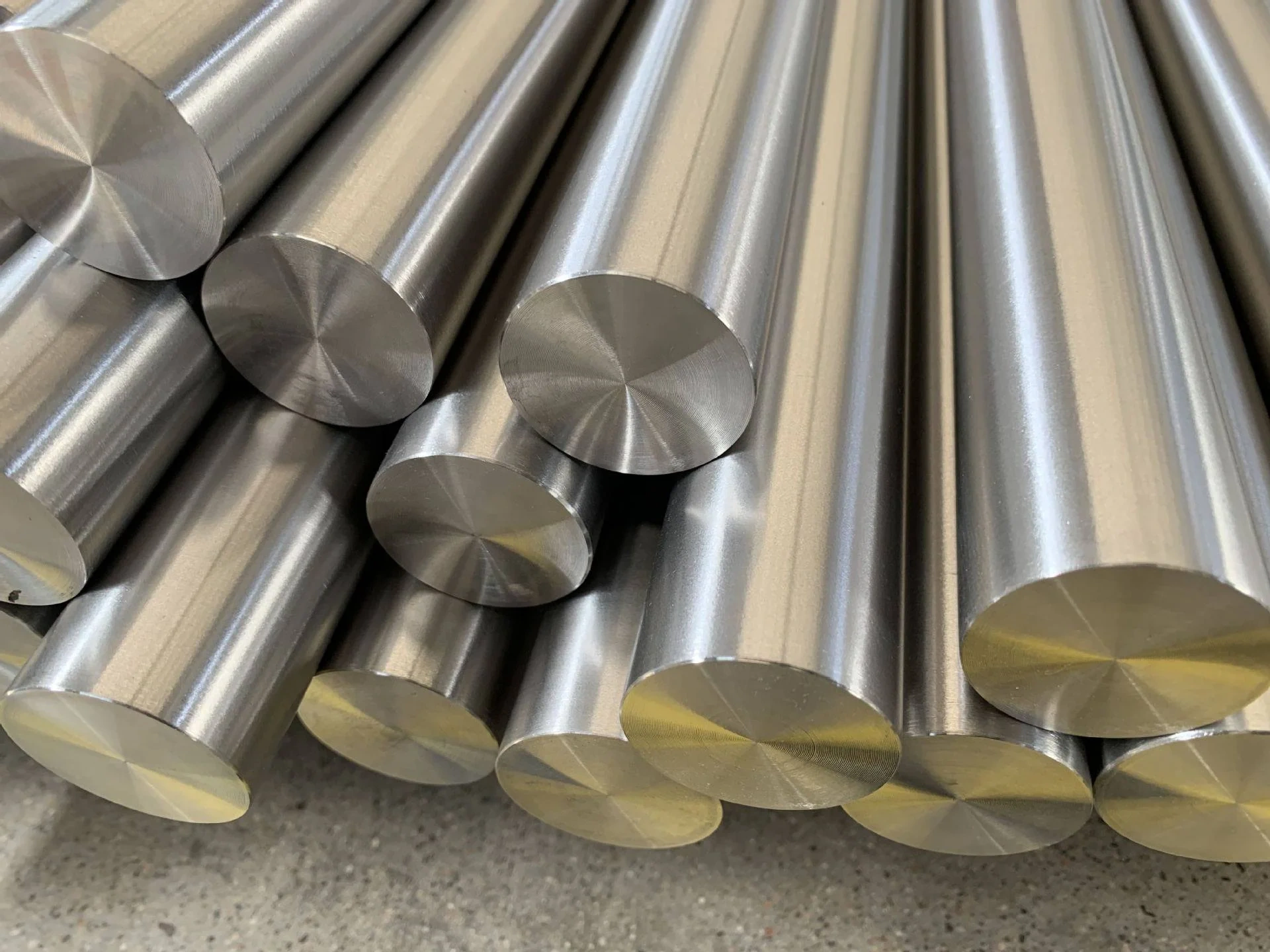

b) Drive shafts, PTO shafts, and rotary components

c) Wear-resistant bushings for high-stress applications

As a trusted agricultural machinery parts manufacturer in Iowa, Fedele Autocore has built its reputation

on delivering superior quality precision components that withstand the demanding conditions of modern farming operations.

Our manufacturing capabilities encompass a wide range of materials specifically chosen for agricultural applications:

Carbon Steel (1045, 4140) for gears, shafts, and structural components

Alloy Steel (4340, 8620) for high-strength transmission parts requiring exceptional durability

Cast Iron (Gray and Ductile) for engine blocks and transmission housings

Stainless Steel (316, 304) for corrosion-resistant components exposed to harsh agricultural environment

Aluminum Alloys (6061, 7075) for lightweight housings and brackets

Bronze and Brass for bushings, bearings, and wear plates

With decades of experience serving agricultural equipment manufacturers, we understand the unique challenges and requirements of farming equipment.

Our CNC machining capabilities utilize the latest technology to deliver precision parts with exceptional consistency.

We work with specialized materials designed for agricultural applications, ensuring optimal performance and longevity.

Every component undergoes rigorous testing and inspection to meet or exceed specifications.

We specialize in agricultural machinery components including hydraulic cylinders, transmission gears, valve bodies, manifolds, splined hubs, tillage tool components, and harvester parts. Our CNC parts in Iowa are designed specifically for agricultural equipment applications.

We work with a comprehensive range of materials including Carbon Steel (1045, 4140), Cast Iron (Gray, Ductile), Stainless Steel (316, 304), Aluminum Alloys (6061, 7075), Alloy Steel (4340, 8620), and Bronze/Brass for specialized applications.

Our tolerance capabilities range from ±0.0002" for critical components like transmission gears and hydraulic pistons to ±0.030" for general structural components. We maintain surface finishes as fine as 8-16 Ra for hydraulic applications.

Yes, as an agricultural machinery parts manufacturer in Iowa located near John Deere headquarters, we have extensive experience manufacturing components that meet John Deere specifications and standards.

Absolutely. Our CNC machining capabilities in Iowa are designed to handle both prototype quantities and large production runs, with scalable manufacturing processes to meet varying demand levels.

Our agriculture equipment precision parts in Iowa serve various applications including tractors, combines, tillage equipment, planters, and harvesting machinery across all major agricultural equipment categories.

We maintain ISO 9001 certification for quality management systems, comply with ASAE (American Society of Agricultural and Biological Engineers) standards, meet SAE standards for mobile equipment, and adhere to OSHA safety requirements.

We implement comprehensive quality control processes including incoming material inspection, in-process monitoring, final inspection, and statistical process control to ensure every CNC part meets specifications.

Yes, we provide complete material certifications, dimensional inspection reports, and any required testing documentation with every shipment to ensure full traceability.

Lead times vary depending on complexity and quantity, but our Iowa location allows us to provide faster turnaround times to regional agricultural equipment manufacturers compared to distant suppliers.

Yes, our experienced engineering team can work with customers to optimize part designs for manufacturability, cost-effectiveness, and performance in agricultural applications.

Absolutely. We provide comprehensive prototyping services to validate designs and manufacturing processes before committing to full production runs.

We need detailed drawings or 3D models, material specifications, quantity requirements, quality standards, and delivery timeline. Our team can also work from samples for reverse engineering applications.

Our Iowa location provides excellent logistics advantages for regional customers. We work with trusted carriers and can accommodate various shipping requirements including expedited delivery when needed.

Yes, we understand the critical nature of agricultural equipment repairs during farming seasons and can prioritize urgent orders to minimize equipment downtime.

Our facility includes multi-axis CNC machining centers, turning centers, and specialized equipment for agricultural component manufacturing, allowing us to handle complex geometries and tight tolerances.

Yes, we have extensive experience machining all types of materials commonly used in agricultural equipment, from various steel grades to aluminum alloys, stainless steel, and specialty alloys.

Yes, we do heat treatment, chrome plating for hydraulic rods, and various surface treatments to meet specific application requirements.