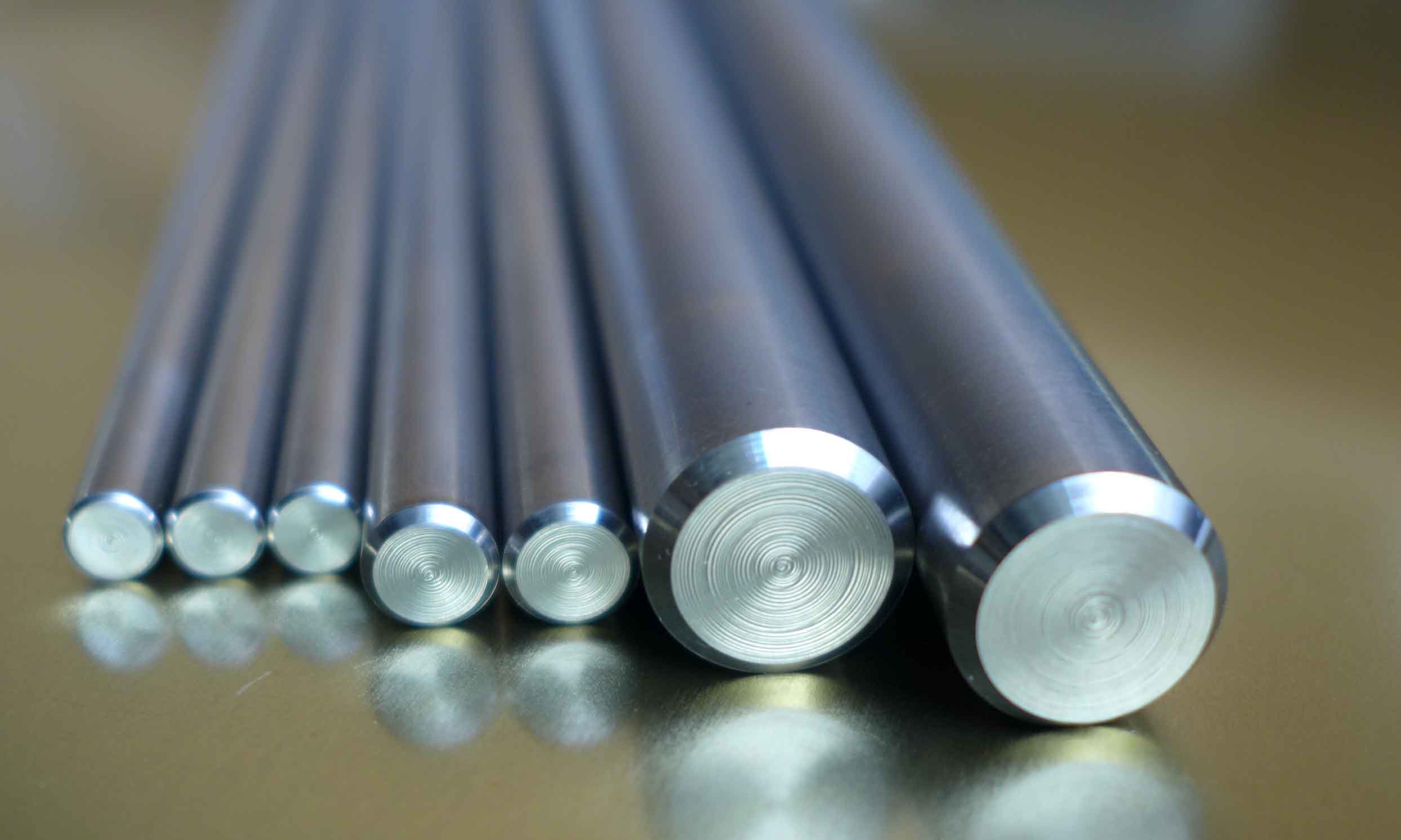

Delivering exceptional precision manufacturing solutions across Australia's major industrial centers. From prototypes to high-volume production runs, we combine cutting-edge technology with decades of engineering expertise to create components that exceed industry standards

Our state-of-the-art CNC equipment and quality control systems ensure consistent, repeatable precision across all manufacturing processes.

| Dimension Category | Standard Tolerance | Precision Tolerance | Ultra-Precision Tolerance |

|---|---|---|---|

| Linear Dimensions | ±0.05mm (±0.002") | ±0.025mm (±0.001") | ±0.0127mm (±0.0005") |

| Hole Diameters | ±0.025mm (±0.001") | ±0.0127mm (±0.0005") | ±0.0063mm (±0.00025") |

| Angular Tolerances | ±0.5° | ±0.25° | ±0.1° |

| Surface Flatness | 0.05mm (0.002") | 0.025mm (0.001") | 0.0127mm (0.0005") |

| Roundness/Cylindricity | 0.025mm (0.001") | 0.0127mm (0.0005") | 0.0063mm (0.00025") |

| Surface Finish (Ra) | 1.6µm (63µin) | 0.8µm (32µin) | 0.2µm (8µin) |

Comprehensive range of materials for diverse Australian industrial applications

Grades like **6061-T6, 7075-T6, 2024-T3**, offering excellent strength, corrosion resistance, and machinability.

Grades like **304, 316L, 17-4 PH**, providing superior corrosion, heat resistance, and weldability.

Includes **1018, 1045, 4140, 4340**, known for high strength and toughness for structural and machine components.

Grades like **D2, A2, H13, M2**, used for tooling and molds, offering high hardness, strength, and abrasion resistance.

Includes **Grade 2, Grade 5 (Ti-6Al-4V), Grade 9**, prized for high strength-to-weight ratio and corrosion resistance.

Such as **Inconel 625/718, Hastelloy C-276, Monel 400**, for exceptional strength and stability at high temperatures.

Grades like **C110, Brass 360, Bronze C932**, known for high thermal/electrical conductivity and corrosion resistance.

Materials like **PEEK, POM (Delrin), PTFE, PEI (Ultem)**, offering chemical resistance and low friction.

Common questions about our CNC machining services

Our typical lead time varies based on part complexity, material, and order quantity. Standard orders usually range from 1-3 weeks. Expedited services are available for urgent requirements.

We primarily accept **STEP, IGES, SolidWorks, AutoCAD DWG/DXF, and PDF** files for quotes. For 3D models, STEP or IGES are preferred to ensure accuracy.

Yes, upon request, we can provide material certifications (MTRs) and comprehensive inspection reports (CMM, First Article Inspection) to ensure full traceability and quality assurance for your parts.

We pride ourselves on flexibility. We accept orders from a single prototype to large production runs. There is no strict minimum order quantity; we tailor our services to your project needs.

Absolutely. We offer comprehensive services from initial rapid prototyping to full-scale production. Our team works with you at every stage to ensure your designs are brought to life efficiently.

We operate under strict quality management systems and are certified to **ISO 9001:2015**. Our commitment to quality ensures all parts meet precise specifications and industry standards.

Yes, we provide a range of secondary operations including **anodizing, powder coating, heat treating, plating, and assembly** to deliver finished parts ready for your application.

We use rigorous in-process inspections, statistical process control (SPC), and advanced metrology equipment to monitor and maintain tight tolerances, ensuring consistent quality from the first part to the last.

Contact Fedele Autocore today for a comprehensive quote and technical consultation. Our engineering team is ready to help bring your precision manufacturing requirements to life.