Delivering world-class precision components for America's energy industry with cutting-edge manufacturing excellence

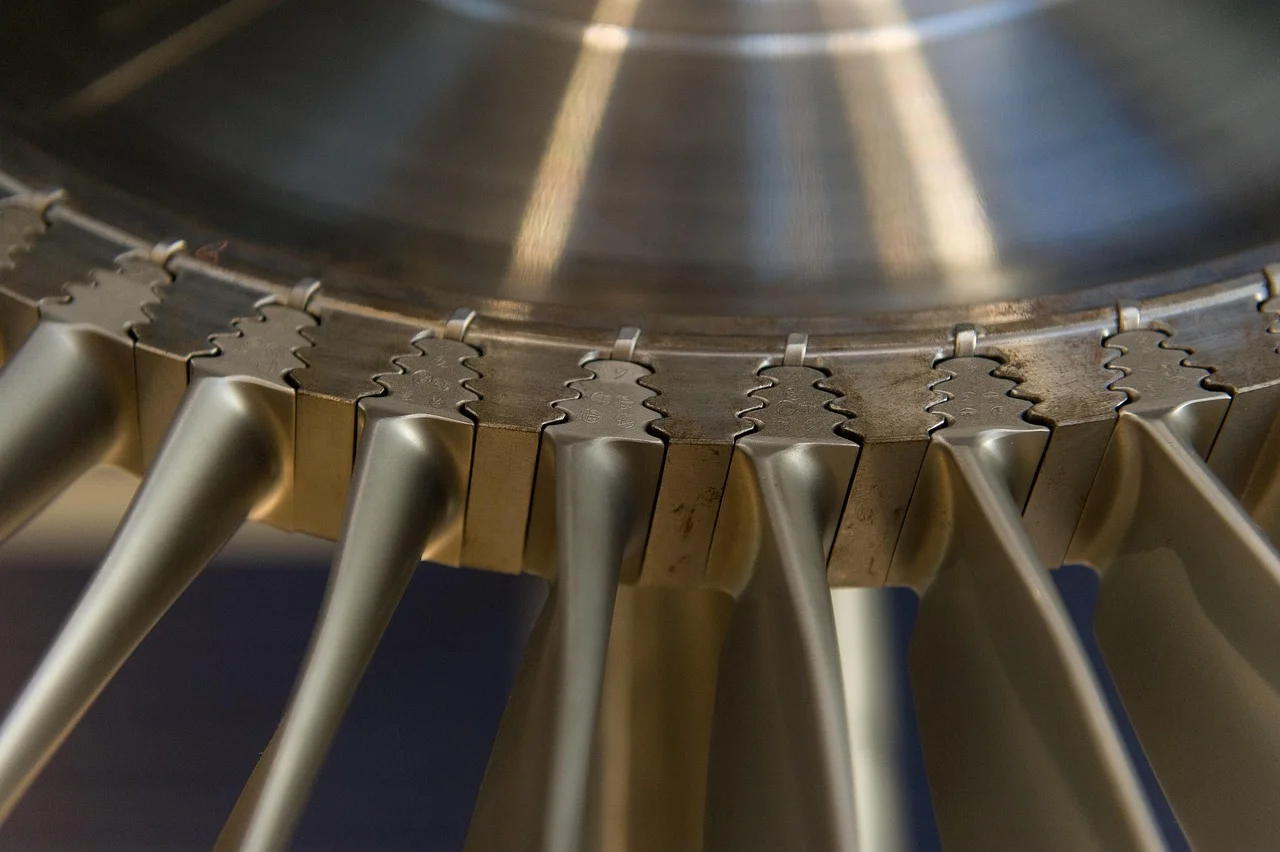

Fedele Autocore is at the forefront of manufacturing precision components for the evolving energy sector. From traditional power generation to renewable energy systems, we deliver critical parts that ensure reliable, efficient operation across wind turbines, solar installations, hydroelectric facilities, and conventional power plants. Our expertise spans turbine components, generator parts, and specialized mounting systems engineered for long-term performance.

Supporting America's transition to sustainable energy, our advanced manufacturing capabilities produce components that withstand extreme environmental conditions, from offshore wind farms to desert solar arrays. We work with corrosion-resistant alloys, high-strength materials, and specialized coatings to manufacture shafts, brackets, fastening systems, and custom assemblies that meet stringent energy industry standards and contribute to a cleaner, more reliable power infrastructure.

Years Experience

Operational Reliability

Future Ready

Precision Tolerance

American energy companies and power generation facilities rely on our precision-engineered components to keep their operations running at peak efficiency. Our specialized manufacturing capabilities ensure every component meets the demanding requirements of modern energy infrastructure.

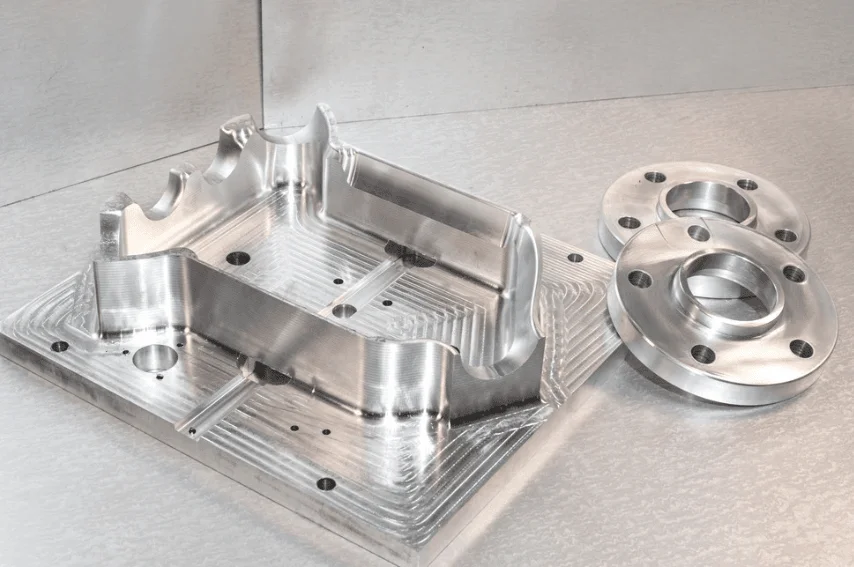

Custom-machined turbine blades, generator housings, transformer parts, and electrical enclosures engineered for maximum reliability in America's diverse power generation facilities.

Precision cooling plates, battery housings, thermal management components, and connection systems designed for advanced energy storage installations throughout the United States.

Corrosion-resistant tracking mechanisms, mounting hardware, inverter housings, and electrical junction components built to withstand America's diverse climate conditions.

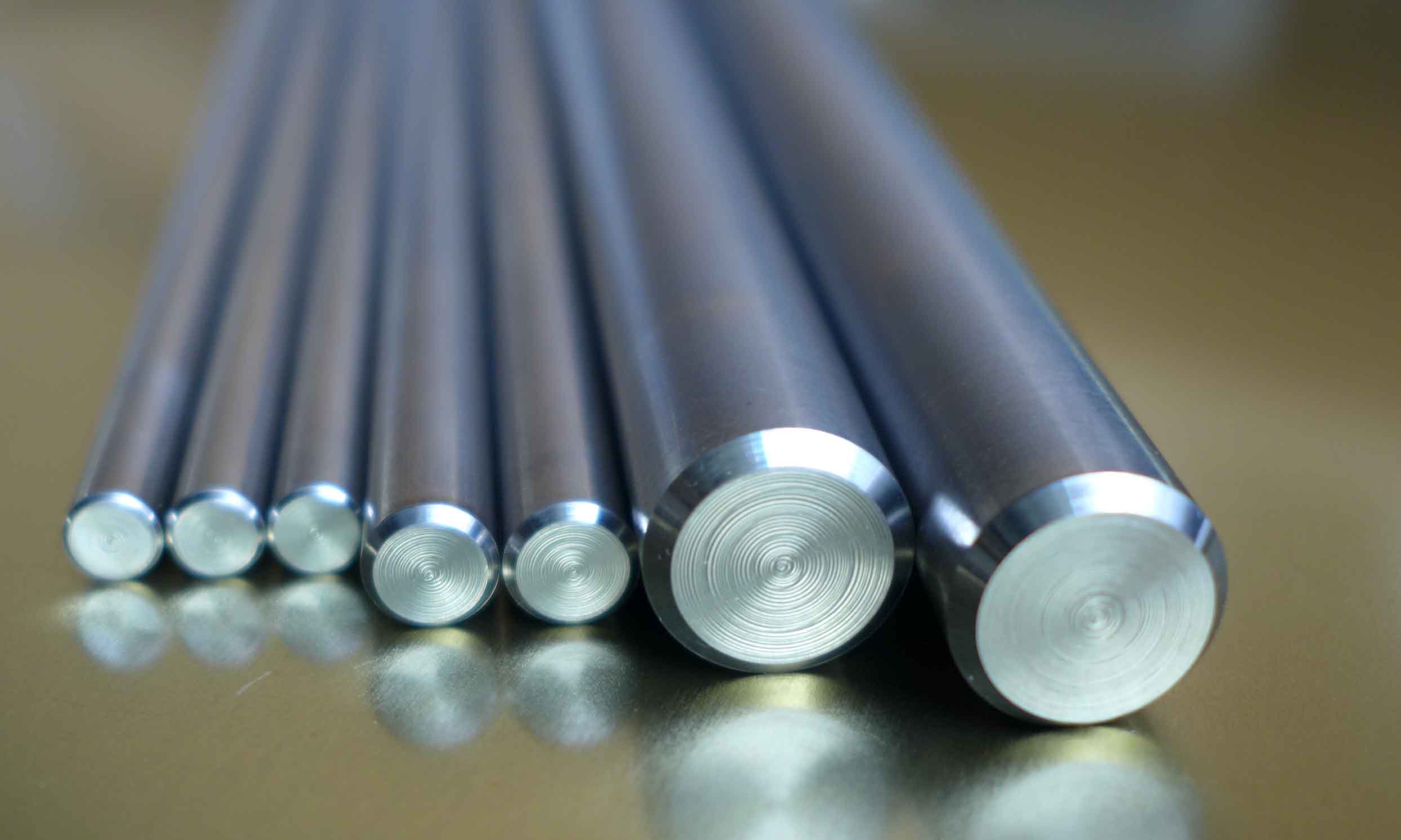

High-strength hub components, pitch control mechanisms, gearbox parts, and bearing assemblies manufactured for America's expanding wind energy infrastructure.

Custom replacement components, retrofit solutions, and upgrade parts ensuring your energy infrastructure maintains optimal performance and regulatory compliance.

Specialized components for drilling equipment, pipeline systems, refinery machinery, and offshore platforms built for America's demanding energy extraction operations.

Our energy sector CNC components are manufactured using only the finest materials, carefully selected for their superior performance in demanding American energy industry conditions. Each material is chosen for specific applications to ensure maximum durability, thermal resistance, and operational efficiency.

Exceptional high-temperature performance for turbine components and combustion systems, maintaining strength at temperatures up to 700°C in power generation applications.

Superior corrosion resistance perfect for offshore energy platforms and coastal installations, providing exceptional durability against saltwater exposure and chemical environments.

Outstanding chemical resistance for oil and gas processing equipment, offering superior performance in highly corrosive environments and extreme operating conditions.

Aerospace-grade strength-to-weight ratio ideal for wind turbine components and solar panel mounting systems, reducing structural loads while maintaining integrity.

High-strength precipitation hardening steel perfect for electrical components and generator parts requiring superior mechanical properties and corrosion resistance.

Exceptional strength and corrosion resistance for critical energy applications, offering unmatched performance in marine and high-stress environments.

Superior pitting and crevice corrosion resistance for pipeline components and offshore applications, providing enhanced durability in chloride-rich environments.

Excellent resistance to acids and alkalis for chemical processing components in energy facilities, maintaining integrity in harsh chemical environments.

Our unwavering commitment to quality ensures every component meets the highest industry standards through comprehensive testing and certification processes.

Every component undergoes rigorous quality assurance testing including dimensional verification, material certification, surface finish analysis, and performance validation. Our commitment to excellence ensures each part meets or exceeds OEM specifications while being perfectly suited to American energy industry demands.

Working closely with leading manufacturers like Fedele Autocore, who bring world-class expertise to serve the American market, we ensure every component meets the highest international standards. Our manufacturing network combines global expertise with local understanding of US energy sector requirements.

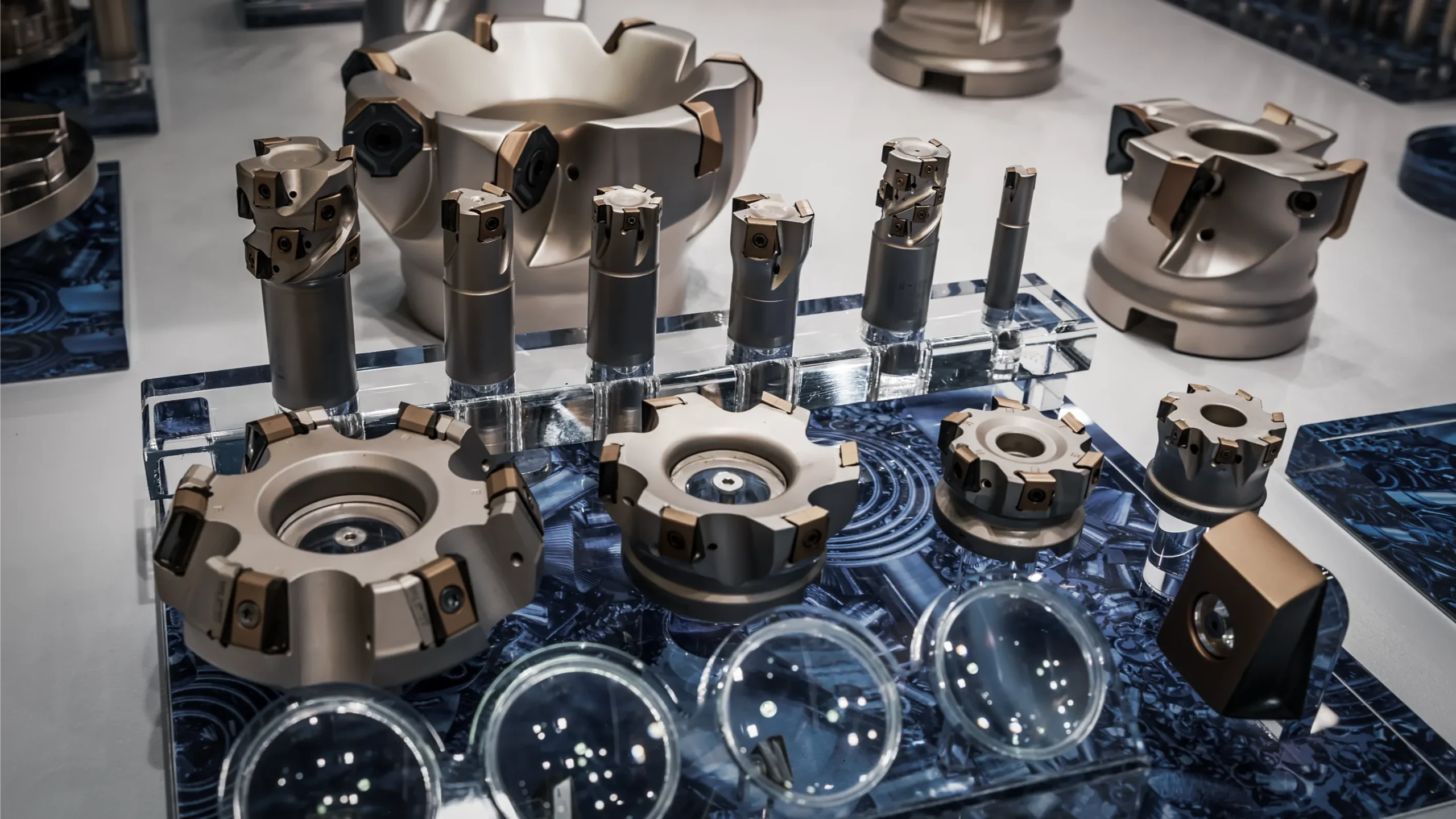

5-axis simultaneous machining for complex geometries with tolerances up to ±0.005mm, perfect for intricate energy component designs and turbine parts.

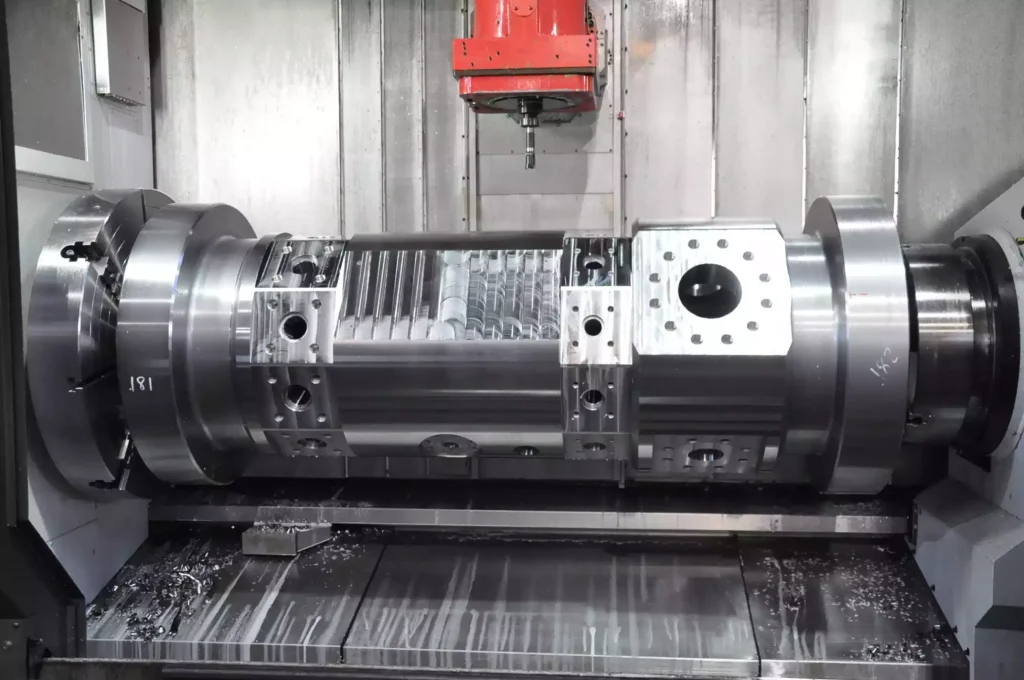

Advanced CNC lathes and mills capable of handling components from small electrical fittings to large generator housings and transformer assemblies.

Anodizing, passivation, heat treatment, and specialized coatings to enhance durability and performance in extreme energy industry operating conditions.

We specialize in components for a comprehensive range of energy sector equipment including power generation turbines, wind energy systems, solar installations, battery storage systems, oil and gas processing equipment, electrical transformers, and offshore platforms. Our expertise covers both renewable energy infrastructure and traditional energy generation facilities throughout the United States.

Our components are specifically engineered for America's demanding energy sector environments. We use materials selected for their resistance to extreme temperatures, pressure, corrosion, vibration, and chemical exposure. Each component undergoes extensive testing including thermal cycling, pressure testing, fatigue analysis, and accelerated corrosion testing to simulate years of operational use in energy facilities.

Absolutely! Custom manufacturing is our specialty. We work directly with energy companies, power plant operators, renewable energy developers, and engineering teams to develop components that meet exact specifications. Our design team can work from technical drawings, samples, or even conceptual requirements to create precision-engineered solutions tailored to your specific energy applications.

We maintain ISO 9001:2015 certification and comply with all relevant ASTM standards as well as international energy sector standards. Our quality management system includes full material traceability, dimensional verification using calibrated precision instruments, and comprehensive documentation for every component produced. We also maintain certifications specific to electrical safety and pressure vessel applications where required.

Lead times vary depending on complexity and quantity, but typically range from 2-4 weeks for standard components and 4-8 weeks for complex custom parts. We understand the critical nature of energy infrastructure and offer expedited services for emergency repairs and scheduled maintenance shutdowns. We also recommend establishing preventive maintenance schedules with spare parts inventory to minimize costly downtime.

Yes, our experienced engineering team provides comprehensive technical support including design optimization, material selection guidance, performance analysis, and troubleshooting. We offer on-site consultation for major energy projects and can assist with retrofitting existing equipment with improved components. Our goal is to help you achieve maximum efficiency, reliability, and compliance from your energy infrastructure.

We have established logistics partnerships to ensure reliable delivery throughout the United States including offshore platforms, remote installations, and renewable energy farms. Components are carefully packaged to prevent damage during transport, and we offer flexible delivery options including express shipping for critical maintenance requirements. We also coordinate with local service providers to ensure convenient delivery scheduling.

Contact our expert team today to discuss your precision CNC machining requirements. We're here to provide the quality components that keep American energy infrastructure running strong.

(+91)-95-700-30000

sales@fedeleautocore.com

Proudly serving energy operations across the United States 🇺🇸