Precision Manufacturing for Critical Defense Applications

Fedele Autocore delivers advanced precision defense manufacturing capabilities throughout the United States with cutting-edge CNC machining technologies. Our certified facility specializes in producing mission-critical components for military, aerospace, and defense applications where precision, reliability, and security are paramount.

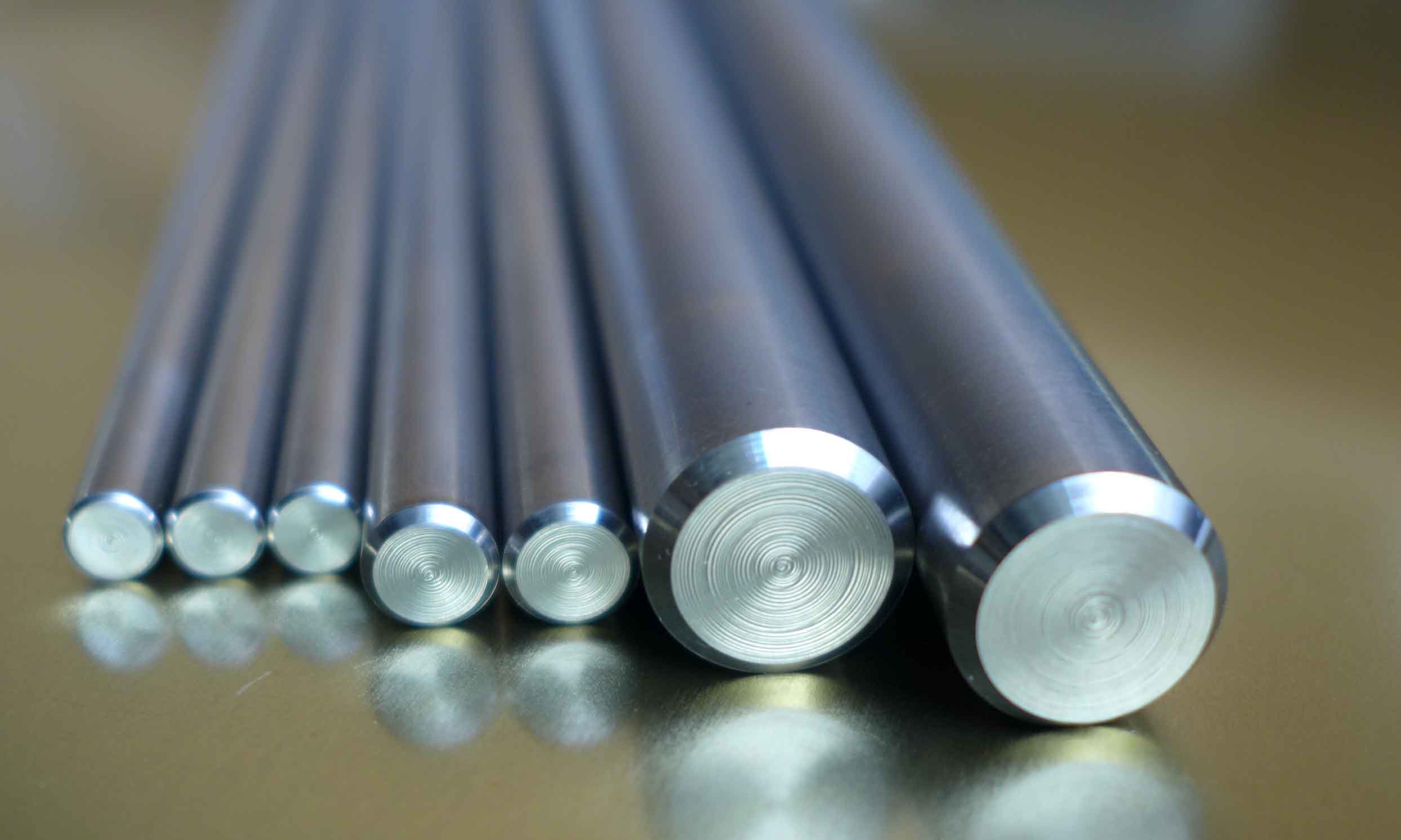

Advanced CNC machining center producing precision defense components

Fedele Autocore specializes in manufacturing high-precision components for defense applications, delivering critical parts that meet the demanding requirements of military and aerospace sectors.

Precision-manufactured structural components, landing gear parts, engine mounts, and critical airframe elements designed to meet stringent aerospace standards and withstand extreme operational conditions.

High-precision manufacturing of firing mechanisms, barrel components, trigger assemblies, and support structures with exact dimensional accuracy for reliable defense system performance.

Armored vehicle parts including suspension components, drivetrain elements, armor mounting brackets, and specialized mechanical systems for military ground vehicles.

Marine-grade precision parts for naval vessels including propulsion system components, deck hardware, navigation equipment housings, and critical structural elements.

Precision housings and mounting systems for military communication devices, radar components, and electronic warfare systems requiring electromagnetic shielding.

Critical guidance system parts, fin assemblies, nose cone components, and precision-manufactured elements for guided missile systems and defense projectiles.

Our advanced CNC machining capabilities deliver exceptional precision across all defense applications, meeting the most stringent military specifications and quality standards.

| PRECISION PARTS | STANDARD TOLERANCE | PRECISION TOLERANCE | CRITICAL APPLICATIONS |

|---|---|---|---|

| Aircraft Wing Brackets | ±0.05mm | ±0.02mm | Flight-critical mounting systems |

| Weapon Barrel Components | ±0.03mm | ±0.01mm | Firing mechanisms, rifling systems |

| Landing Gear Assemblies | ±0.08mm | ±0.03mm | Aircraft landing systems |

| Propeller Hub Components | ±0.1mm | ±0.05mm | Naval propulsion systems |

| Radar Mount Housings | ±0.15mm | ±0.08mm | Communication equipment mounts |

| Missile Guidance Fins | ±0.02mm | ±0.005mm | Precision flight control |

We work with aerospace and defense-grade materials, ensuring all components meet military specifications for durability, strength, and performance in extreme environments.

Superior strength-to-weight ratio, excellent corrosion resistance, ideal for aerospace and high-stress applications.

High corrosion resistance, excellent mechanical properties, suitable for marine and weapon applications.

Lightweight yet strong, excellent machinability, commonly used in aircraft structural components.

Exceptional high-temperature performance, oxidation resistance, critical for jet engine components.

High strength and toughness after heat treatment, ideal for weapon barrels and critical stress components.

Superior high-temperature strength and oxidation resistance for extreme environment applications.

We maintain ISO 9001:2015, AS9100D aerospace quality management certification, and comply with ITAR regulations for defense manufacturing. Our facility undergoes regular audits to ensure compliance with MIL-SPEC and DoD standards.

Lead times vary based on complexity and material requirements. Standard components typically require 2-4 weeks, while complex multi-axis parts may take 4-8 weeks. We offer expedited services for critical defense projects.

Yes, we provide complete material certifications including mill test certificates, chemical composition reports, and full traceability documentation from raw material to finished component as required by defense standards.

We utilize CMM inspection, optical measurement systems, surface roughness testing, and coordinate measuring machines. All parts receive first article inspection reports (FAIR) and dimensional inspection reports as required.

Yes, our facility is approved for handling classified defense projects. We maintain appropriate security clearances and follow strict protocols for classified material handling and secure manufacturing processes.

Our facility can handle both prototype and production volumes. We have multiple CNC machining centers and can scale production to meet large defense contracts while maintaining strict quality standards and delivery schedules.

Get precision manufacturing solutions for your critical defense applications. Contact Fedele Autocore today for a consultation and quote.