Delivering precision-engineered CNC components for the construction industry across the United States. From structural assemblies to custom architectural hardware, we manufacture with uncompromising quality and precision.

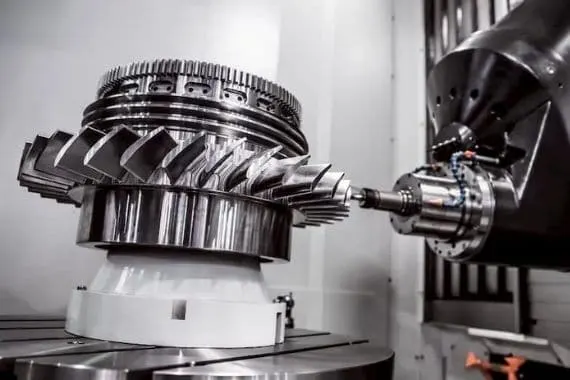

Fedele Autocore manufactures precision-engineered components that drive America's construction sector. From heavy equipment components to structural fastening assemblies, our manufacturing capabilities ensure durability and reliability across demanding job sites. We produce critical parts for excavators, cranes, concrete machinery, and material handling equipment that maintain productivity on your projects.

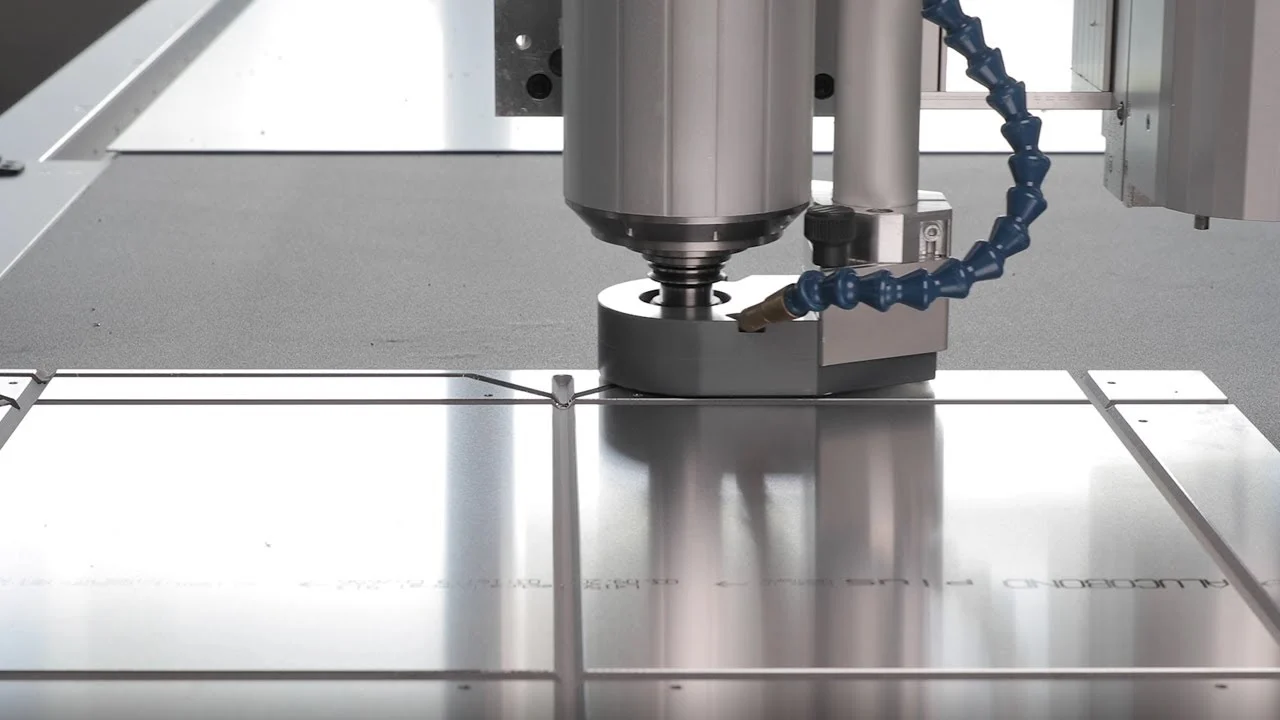

Our advanced CNC machining facilities handle hardened steel pins and bushings, custom hydraulic cylinder assemblies, and wear-resistant components. Serving construction equipment manufacturers, general contractors, and maintenance operations throughout the United States, we deliver parts meeting precise dimensional specifications while withstanding harsh operational environments including dust, vibration, and substantial loading forces.

Years Experience

Equipment Parts Made

Hardened Components

Precision Tolerance

We utilize only premium materials to ensure durability, strength, and precision in every component we manufacture.

Advanced multi-axis capabilities for complex geometries and reduced setup times

Optimized cylindrical part manufacturing with fast processing speeds and automation capabilities

High-precision milling for complex 3D shapes with excellent surface finishing and dimensional accuracy

We consistently achieve tolerances of ±0.01mm for critical dimensions. For construction applications, we typically maintain ±0.1mm to ±0.05mm depending on component specifications and material requirements.

Yes, we provide complete material traceability including Mill Test Certificates, ASTM compliance documentation, and hardness verification reports. All materials are sourced from certified suppliers and meet US construction standards.

Lead times vary based on complexity and order volume. Standard components: 5-10 business days. Complex or high-volume orders: 2-4 weeks. Expedited orders can be accommodated with our 24/7 production capabilities.

Absolutely. We have successfully delivered components for projects ranging from residential construction to major infrastructure developments. Our production capacity and project management systems are designed to handle high-volume orders while maintaining quality standards.

Yes, our engineering team provides design optimization for manufacturability, material selection guidance, and cost reduction strategies while ensuring structural integrity and compliance with US construction standards.

We maintain ISO 9001:2015 certification with comprehensive quality control including CMM inspection, material verification, dimensional validation, and surface finish analysis. Every component undergoes thorough inspection before shipment.

Yes, we regularly machine weathering steel and specialty materials for outdoor construction applications. We understand the unique properties and machining parameters required for these materials.

We partner with certified finishing specialists throughout the United States to provide powder coating, hot-dip galvanizing, anodizing, and other surface treatments required for construction applications.

Contact Fedele Autocore today for precision CNC machining solutions that meet the demanding requirements of America's construction industry.

(+91)-95-700-30000

info@fedeleautocore.com

sales@fedeleautocore.com

New York, Los Angeles, Chicago

Nationwide Service