Manufacturing high-precision automotive components for performance applications since 1999. Serving customers across the United States with competitive pricing and uncompromising quality.

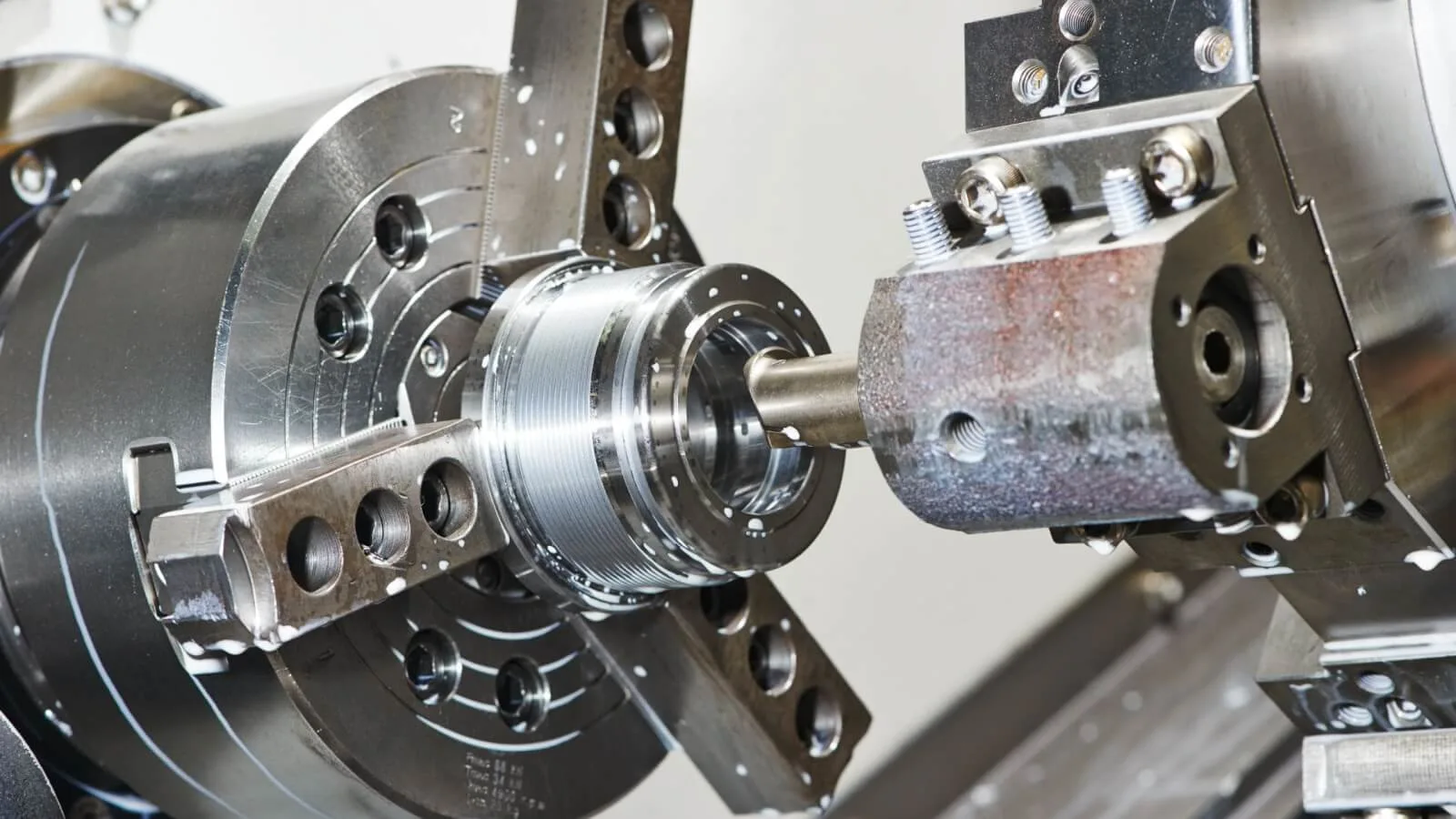

Beginning as a specialized precision shop, Fedele Autocore has evolved into a trusted source for high-performance automotive component manufacturing. Our team at Fedele Autocore, introduced traditional European precision craftsmanship to American automotive engineering, blending meticulous attention to detail with advanced CNC manufacturing technology.

Today, our experienced machinists and technical staff operate state-of-the-art multi-axis CNC equipment capable of achieving tolerances that exceed industry standards. We serve customers throughout the United States with competitive pricing, delivering components for applications ranging from street performance builds to professional racing programs.

Years Experience

Precision Tolerance

Components Designed

Certified Quality

From prototype development to production runs, we manufacture the precision components that power vehicles across America.

We manufacture precision cylinder heads, valve components, and crankshaft assemblies with tolerances that ensure long-lasting engine performance. Our engineering has contributed to numerous high-performance builds.

Precision gear assemblies, input shafts, and transmission housings engineered to handle substantial torque loads. From daily drivers to competition applications, our transmission components deliver dependable performance.

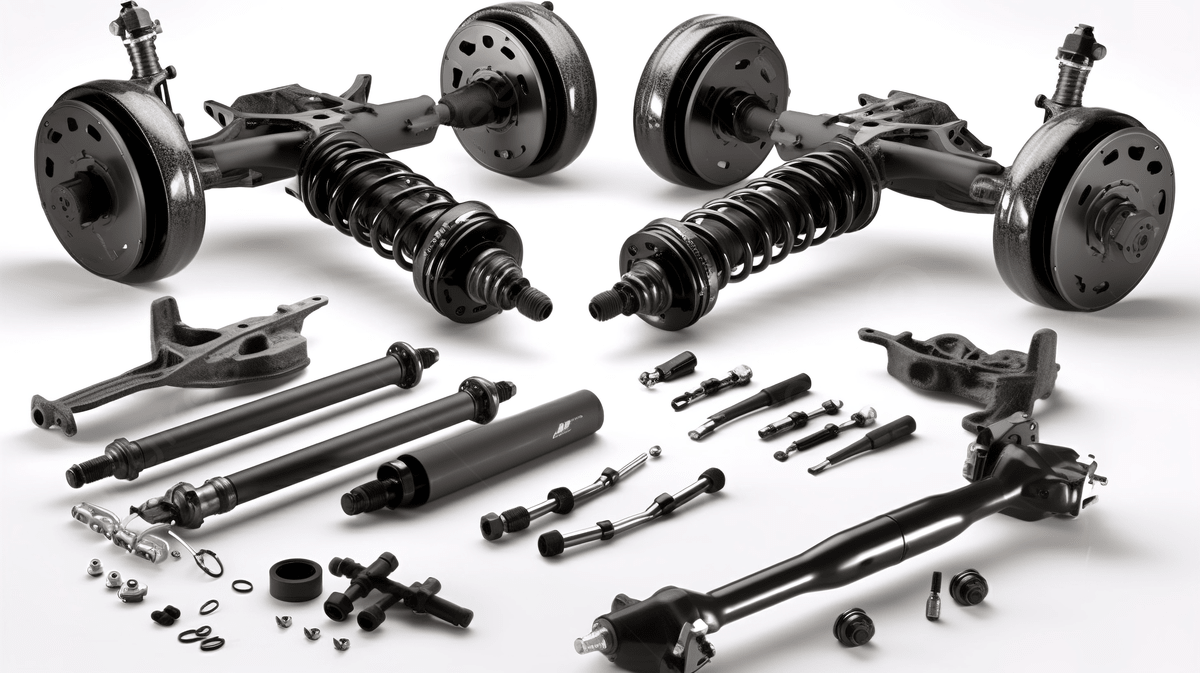

Control arm assemblies and mounting hardware engineered to enhance vehicle handling characteristics. We've produced custom suspension components for autocross, road racing, and performance street applications.

Brake system integrity demands absolute precision. Our rotors, caliper housings, and mounting components are manufactured to withstand extreme thermal conditions and braking forces in demanding applications.

Fuel rail assemblies, injector housings, and pump components engineered for consistent fuel delivery. Precision machining and appropriate material selection ensure reliable fuel system operation under various conditions.

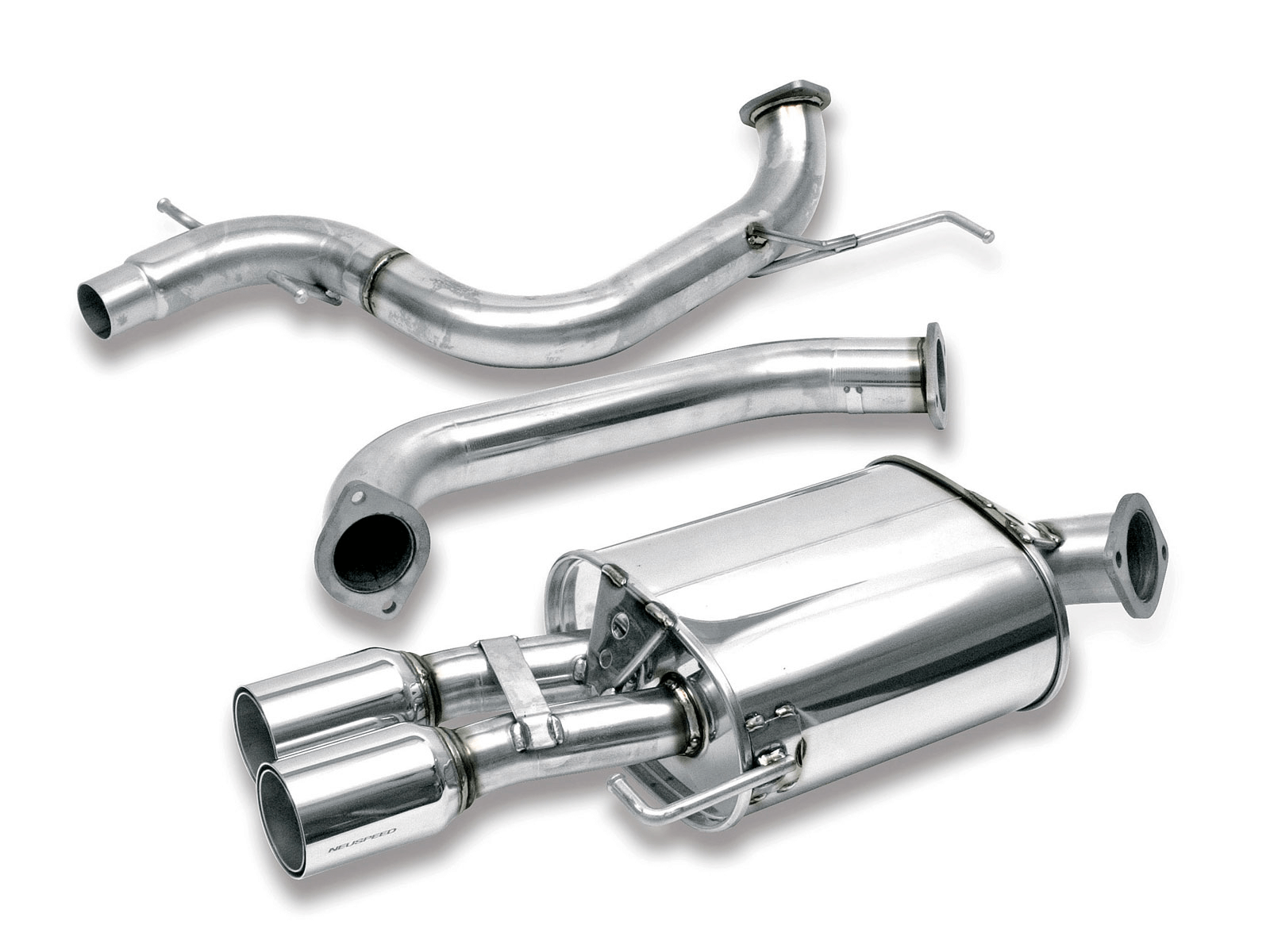

Manifold flanges and exhaust hardware manufactured to resist warping and thermal fatigue. We select appropriate high-temperature materials and machine them to specifications that ensure longevity in extreme heat applications.

Turbocharger housings and compressor components machined to aerospace-level tolerances. For forced induction applications, precision machining at micro-level dimensions directly impacts performance and reliability.

Differential housings, gear carriers, and associated hardware engineered to transmit substantial power. From street performance to dedicated competition vehicles, our differential components withstand demanding use.

Steering rack assemblies, pinion gears, and mounting components manufactured for precise vehicle control. Eliminating tolerance stack-up and component play results in responsive steering feel that drivers notice immediately.

Radiator tank assemblies, water pump housings, and thermostat components that maintain optimal operating temperatures. Efficient thermal management begins with precision-manufactured cooling system components.

Custom camshaft profiles, intake manifold assemblies, and specialized performance components. When standard parts don't meet requirements, we manufacture the custom pieces that deliver competitive advantages.

Competition-proven components for racing teams that demand zero-failure tolerance. From club racing to professional motorsport series, our components consistently perform with pricing structures suitable for various racing budgets.

We maintain standard tolerances of ±0.01mm on typical production work, with capabilities extending to ±0.002mm for ultra-precision applications. Our Mazak and Haas machining centers undergo weekly calibration protocols, and all components receive CMM verification before shipment.

Our material capabilities encompass standard automotive materials including 6061 and 7075 aluminum alloys, 4140 and 4340 steel grades, plus stainless varieties such as 316 and 17-4 PH. For specialized applications, we machine titanium alloys and exotic materials including Inconel. Material selection depends on specific application requirements.

Standard lead time ranges from 5-15 days based on component complexity and specifications. For urgent requirements, expedited processing can typically deliver within 2-3 days. Racing teams receive priority scheduling during competition seasons, as we understand time-critical needs in motorsport applications.

Comprehensive inspection reports accompany every production run, documenting actual measurements against specified tolerances. We maintain ISO 9001 certification and can provide complete material certifications and traceability documentation when required for quality assurance purposes.

We handle projects ranging from individual prototype components to production runs of several thousand units. Small batch manufacturing represents our core competency, though we maintain capacity for larger volume production. All projects receive consistent attention to quality standards regardless of quantity.

We accept various CAD formats including SolidWorks files, AutoCAD drawings, STEP files, and traditional dimensioned prints. Our programming team can work with any standard engineering documentation. We frequently recommend design optimizations to improve manufacturability without compromising functionality.

Patterson Motorsport

Fedele's team understand precision engineering. We required custom transmission housings for our touring car program, and the dimensional accuracy was exactly as specified. Competitive pricing for the quality delivered.

Velocity Racing Team

We've relied on Fedele for brake rotor manufacturing for three racing seasons. When braking from 130+ mph into tight corners, component precision isn't negotiable. Their work consistently meets our exacting standards at fair pricing.

Boost Dynamics

From grassroots racing to professional motorsport programs, our components have competed nationwide. We provide US-wide shipping with competitive pricing structures that fit various project budgets.