Advanced manufacturing excellence delivering mission-critical components for America's aerospace industry with unmatched precision

Fedele Autocore delivers precision-engineered aerospace components that meet the exacting demands of America's aviation sector. We specialize in manufacturing critical flight systems, structural assemblies, propulsion components, and avionics housings that adhere to the most stringent aerospace specifications. Our manufacturing philosophy centers on zero-defect production, complete material certification, and comprehensive quality documentation that supports both commercial and defense aerospace applications.

Our advanced machining facilities process aerospace-certified materials including titanium Ti-6Al-4V, aluminum 7075-T6, Inconel superalloys, and precipitation-hardened stainless steels. Each component is manufactured in temperature-controlled environments and validated through coordinate measuring machine inspection. We support FAA compliance, maintain full traceability protocols, and deliver parts that perform flawlessly in high-stress environments from sea level to stratospheric altitudes.

Years Experience

Quality Standards

Material Traceability

Precision Tolerance

Our comprehensive portfolio of precision-manufactured components supports America's aerospace leadership

Precision-crafted turbine blades, compressor housings, fuel nozzles, and combustion liners engineered for optimal performance with exceptional dimensional accuracy and superior metallurgical properties.

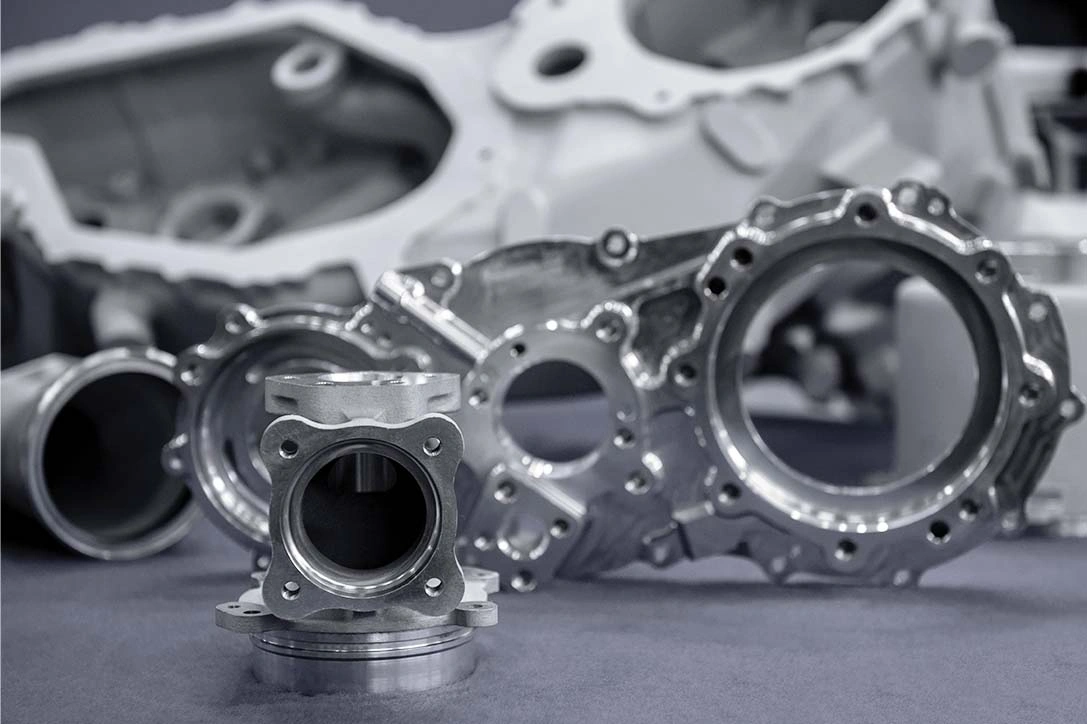

Critical landing gear components including actuator bodies, strut assemblies, shock absorber housings, and wheel hubs manufactured for maximum durability and structural integrity.

Lightweight yet robust wing spars, fuselage stringers, bulkhead fittings, and structural brackets engineered from high-strength alloys to meet rigorous aerospace load requirements.

Precision actuator housings, control valve bodies, servo mount assemblies, and linkage components ensuring responsive and reliable aircraft flight control performance.

Electromagnetic interference shielded enclosures, thermal management heat sinks, and precision mounting frames protecting critical avionics in demanding flight environments.

Precision hub components, blade retention systems, pitch change mechanisms, and drive train elements for both propeller-driven and rotary-wing aircraft platforms.

We machine the full spectrum of aerospace-certified materials, each selected for optimal performance in demanding flight applications.

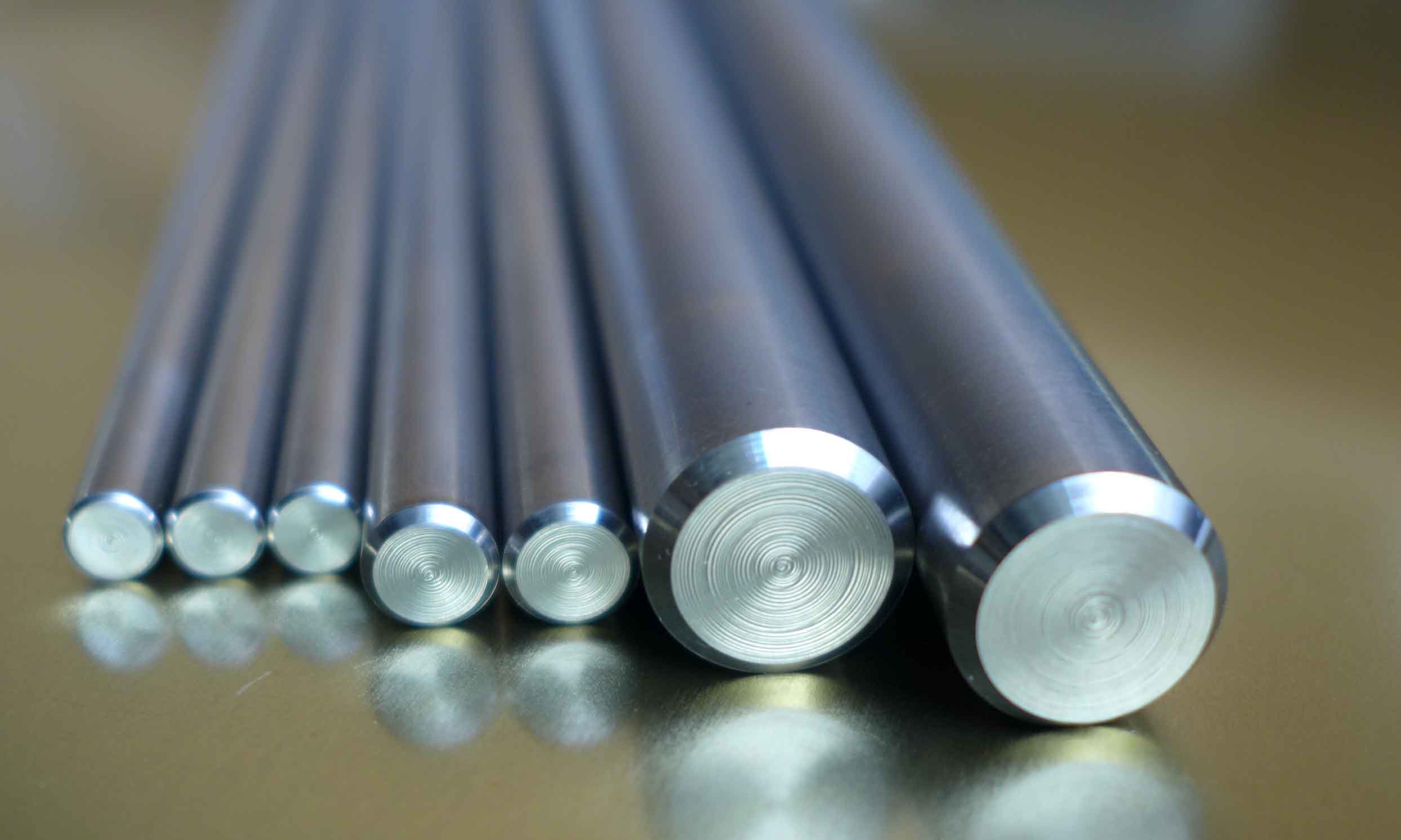

Ti-6Al-4V, Ti-6Al-2Sn-4Zr-6Mo delivering exceptional strength-to-weight performance with outstanding corrosion resistance for critical applications

7075-T651, 2024-T351, 6061-T6 offering superior strength characteristics and excellent machinability for structural aerospace components

Inconel 625, Inconel 718, Waspaloy providing exceptional high-temperature strength and oxidation resistance for turbine applications

17-4 PH, 15-5 PH, 316L stainless offering robust corrosion resistance and high mechanical strength for aerospace hardware

4340 alloy steel, 300M, Maraging steels providing superior toughness and impact resistance for high-stress aerospace components

Cobalt-Chrome alloys, Beryllium Copper, specialty composites for advanced aerospace applications requiring unique material properties

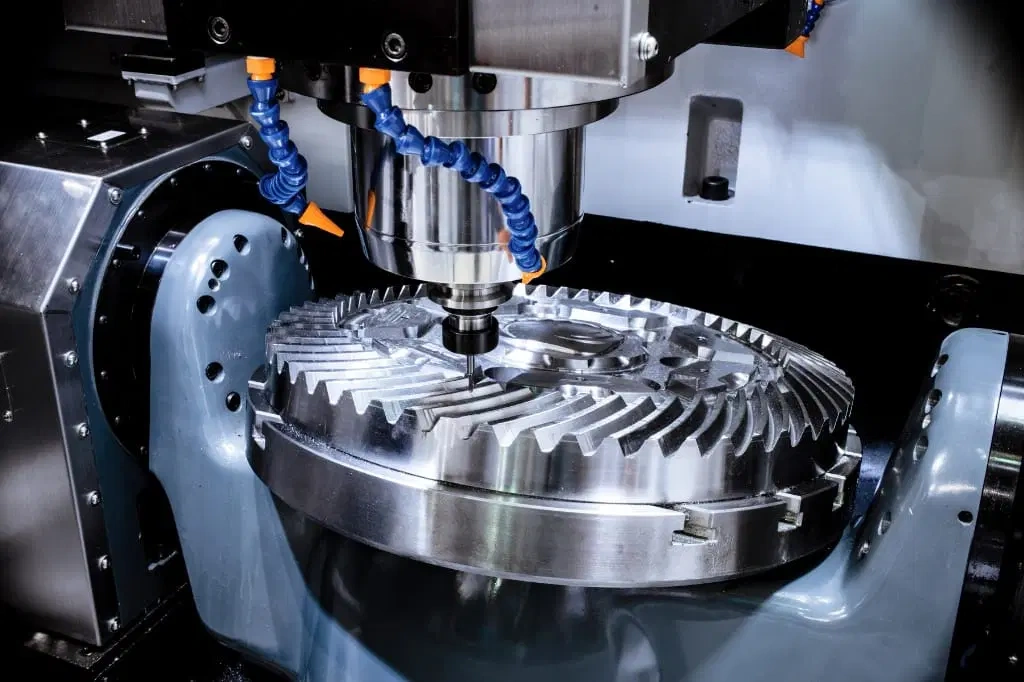

Aerospace CNC machining demands ultra-precise tolerances, certified materials, and comprehensive documentation protocols. Components must endure extreme operating conditions including temperature variations, intense vibration, and structural stress while maintaining critical dimensions. Our processes encompass full material certification, coordinate measuring machine verification, and adherence to AS9100 aerospace quality standards.

We maintain AS9100D certification and comply with FAA regulations for US aerospace manufacturing. Every component undergoes thorough dimensional inspection using advanced CMM equipment, with complete documentation packages including material certifications and conformance reports. Our quality management system ensures full traceability from raw material receipt through final delivery.

Our manufacturing capabilities achieve tolerances as precise as ±0.0001" (±0.0025mm) with surface finishes reaching 4 Ra microinches. We employ state-of-the-art 5-axis machining centers, precision tooling systems, and environmentally controlled production areas to consistently deliver these exacting standards across all aerospace components.

Yes, we serve US aerospace manufacturers from initial design validation through full-scale production runs. Our adaptable manufacturing infrastructure supports single-piece prototypes for engineering development as well as high-volume production quantities, maintaining identical quality standards and documentation requirements regardless of order size.

Lead times depend on component complexity, material specifications, and order volume. Standard parts typically require 2-3 weeks, while intricate assemblies or specialized materials may need 4-8 weeks. We provide detailed production schedules during quotation and maintain transparent communication throughout manufacturing to keep US customers informed of progress.

Complete documentation packages accompany every aerospace shipment, including certified material test reports, certificates of conformance, dimensional inspection data, and full traceability records. We maintain comprehensive documentation to support FAA compliance, customer audits, and US aerospace regulatory requirements throughout the component lifecycle.